Logistics performance is more than just managing transportation—it’s the heartbeat of any successful business. Understanding and optimizing it is key to maximizing profitability and efficiency. In this comprehensive guide, we’ll delve deep into why logistics performance is critical, how to measure it, and the tools and strategies to enhance it.

Why is Logistics Performance Essential?

In today’s globalized world, businesses are interconnected in a vast web of suppliers, manufacturers, and consumers. The effectiveness with which products and services move within this web is determined by logistics performance. Its importance can’t be overstated, and here’s why:

1. Boosting Profitability:

Efficient logistics often equate to reduced costs. From fuel consumption in transportation to warehouse storage optimization, businesses that nail their logistics can often operate at lower costs, thereby boosting profitability.

2. Operational Efficiency:

Efficient logistics processes minimize waste—both in terms of time and resources. Whether it’s ensuring that trucks aren’t traveling half-empty or making sure warehouses aren’t overstocked, superior logistics performance ensures that businesses run like well-oiled machines.

3. Meeting Consumer Expectations:

In the age of next-day deliveries and instant gratification, consumers expect quick and reliable service. Businesses that can guarantee timely deliveries and consistent service quality often see higher customer retention rates.

4. Risk Mitigation:

Efficient logistics performance isn’t just about speed; it’s also about reliability and predictability. A business with a well-managed logistics arm can better navigate disruptions, whether they’re caused by global events or local hiccups.

5. Environmental Responsibility:

With the growing emphasis on sustainability and eco-friendly operations, efficient logistics performance can reduce a business’s carbon footprint. Efficient routes, optimized packaging, and waste reduction all contribute to a greener operation.

6. Enhanced Competitiveness:

In an increasingly competitive global market, logistics performance can be a distinguishing factor. Companies with better logistics can promise (and deliver) better services to their customers, setting them apart from the competition.

In essence, logistics performance isn’t just a backend operation; it’s at the forefront of customer satisfaction, business growth, and sustainable operations. Businesses that prioritize it are often more resilient, more profitable, and more in tune with their customers’ needs.

Metrics to Measure Logistics Performance:

To truly grasp how well a business’s logistics operations are functioning, it’s essential to have a robust set of metrics in place. These metrics provide a snapshot of the present and a roadmap for future improvements.

Here are 9 critical indicators + 1 bonus:

- Logistics Cost: This metric measures the cost-effectiveness of logistics processes. Breaking down costs, such as transportation, warehousing, labor, and packaging, gives businesses an understanding of where they might be overspending and where efficiency can be improved.

- Delivery Speed: Speed is of the essence in today’s fast-paced market. This metric evaluates how swiftly products reach customers, considering factors like transit time, loading and unloading durations, and processing speed at distribution centers.

- Reliability: It’s not just about speed, but also consistency. This metric gauges the predictability of deliveries. A high-reliability score indicates that deliveries consistently meet promised timelines, instilling trust among customers.

- Inventory Management: Managing stock efficiently is crucial for both meeting customer demand and keeping costs in check. Metrics like ‘Days Inventory Outstanding’ (DIO) and ‘Inventory Turnover Rate’ can offer insights into how effectively stock is being managed.

- Customer Service: A logistics department’s responsiveness and ability to address issues promptly are paramount. Customer feedback, resolution times, and service consistency are just a few metrics that can help gauge this aspect.

- Return Rates: High return rates might point to problems in the logistics process. Whether it’s due to damaged goods, incorrect deliveries, or other issues, monitoring return rates can provide insights into potential areas of improvement.

- Warehouse Efficiency: Metrics such as ‘Order Lead Time’, ‘Warehouse Capacity Usage’, and ‘Picking Accuracy’ shed light on the efficiency of warehousing operations, ensuring optimal usage of space and resources.

- Transportation Efficiency: Fuel consumption rates, vehicle maintenance costs, and route optimization are key indicators here. Efficient transportation not only cuts costs but also reduces a business’s environmental impact.

- Supplier and Partner Performance: Building a resilient supply chain means having reliable partners. Evaluating the performance of suppliers and logistics partners ensures that the entire chain functions smoothly.

- Bonus – Technology and Automation ROI: As businesses invest in logistics technology and automation, it’s vital to measure the return on these investments. This ensures that technology integrations are yielding the desired efficiency improvements.

Diving deep into these dynamic metrics, businesses can keep their finger on the pulse of their logistics operations. With every number crunched and every trend analyzed, they’re not just staying ahead of the curve—they’re dancing on it, ensuring operations are agile, cost-effective, and always attuned to the heartbeat of their customers

The Future of Logistics: Automation and Analytics

In an era where the digital transformation wave is sweeping across industries, logistics is not left behind. The sector is on the brink of a revolution, led by groundbreaking innovations in automation and the power of analytics. Here’s what the future holds:

- Smart Warehouses: Gone are the days of manual stock checks and handwritten logs. Automated storage and retrieval systems (AS/RS), paired with IoT devices, are transforming warehouses into responsive ecosystems. Sensors detect stock levels in real-time, robotics assist in packaging, and AI algorithms predict stock replenishment needs, all leading to unparalleled efficiency.

- Predictive Analytics: By harnessing vast amounts of data, companies can forecast trends with a precision that was previously unimaginable. Predictive analytics tools can anticipate shipment delays, forecast demand spikes, and even preempt maintenance needs, thus reducing downtimes.

- Autonomous Vehicles: Self-driving trucks and drones are not just sci-fi concepts anymore. With advancements in machine learning and AI, the logistics industry is gearing up for a future where deliveries might not need human intervention, ensuring faster and safer transportation.

- Blockchain in Logistics: Transparency and traceability are crucial in logistics. Blockchain technology offers a secure and transparent way to track goods throughout the entire supply chain. This decentralized ledger system reduces fraud, ensures product authenticity, and accelerates customs clearance.

- Dynamic Route Optimization: With real-time analytics, transportation routes can be optimized on-the-fly, considering variables like traffic patterns, weather conditions, and delivery priorities. This not only speeds up deliveries but also reduces fuel consumption.

- Virtual Reality (VR) and Augmented Reality (AR): Training and operations in logistics can benefit significantly from VR and AR. From simulating complex warehousing tasks for training purposes to using AR for efficient package sorting and handling, these technologies are set to redefine hands-on operations.

- Integration of Advanced Analytics and Customer Service: Personalized customer experiences are becoming the norm, and logistics is no exception. By analyzing customer behavior and preferences, logistics companies can tailor their services, from delivery time slots to personalized package handling instructions.

Embracing automation and analytics is no longer optional for businesses aspiring to lead in the logistics arena.

As the boundaries of what’s possible continue to expand, companies at the forefront of adopting these innovations will set the gold standard in efficiency, customer satisfaction, and operational excellence.

Strengthening the Supply Chain:

The heartbeat of any logistics-driven enterprise lies in the resilience of its supply chain. A fortified supply chain stands as a vanguard against global disruptions, economic undulations, and the ever-evolving tapestry of consumer demands. Embracing digital transformation, modern businesses harness the prowess of Enterprise Resource Planning (ERP) systems combined with the incisiveness of advanced analytics. This digital embrace gifts them a real-time window into their operations, stretching from procurement’s initial stages to the final chapters of distribution.

Yet, in an age of unpredictability, diversification is the key. Smart businesses avoid placing all their eggs in one basket, choosing instead to cast a wider net with diversified suppliers, strategies, and logistic alliances. This broad approach equips them to better navigate the turbulent waters of political upheavals, environmental calamities, or global health crises.

While the environmental drumbeat grows louder, businesses are realizing that a green supply chain isn’t just an ecological responsibility; it’s a strategic masterstroke. Sustainable practices are becoming synonymous with cost savings, positive brand narratives, and gateways to previously untapped markets. Moreover, in the intricate dance of supply chain operations, transparent communication is emerging as the star performer. Through clear, consistent, and collaborative dialogues, businesses foster a milieu of trust and seamless operations.

The modern supply chain is not just about reactive measures; it’s about predictive foresight. Leveraging the magic of machine learning and AI, enterprises are now peering into the future, anticipating market demands and potential roadblocks. And as the technological landscape morphs, the continuous upskilling of the workforce becomes a non-negotiable priority, ensuring the human touch in the supply chain remains adept and relevant.

Inventory, often considered the lifeblood of operations, demands a Goldilocks approach—just right. By integrating smart inventory management solutions attuned to market nuances, businesses can strike this elusive balance. But beyond technology and strategies, the true essence of a resilient supply chain lies in its relationships. By cultivating robust bonds with suppliers, partners, and even competitors, businesses lay the foundation for collaborative innovations and shared triumphs in adversity.

As we reflect on the multifaceted journey of supply chain fortification, it becomes evident that businesses poised for future success are those that seamlessly weave innovation, diversification, and robust relationships into their supply chain tapestry.

Delving Deeper: Supply Chain Management (SCM)

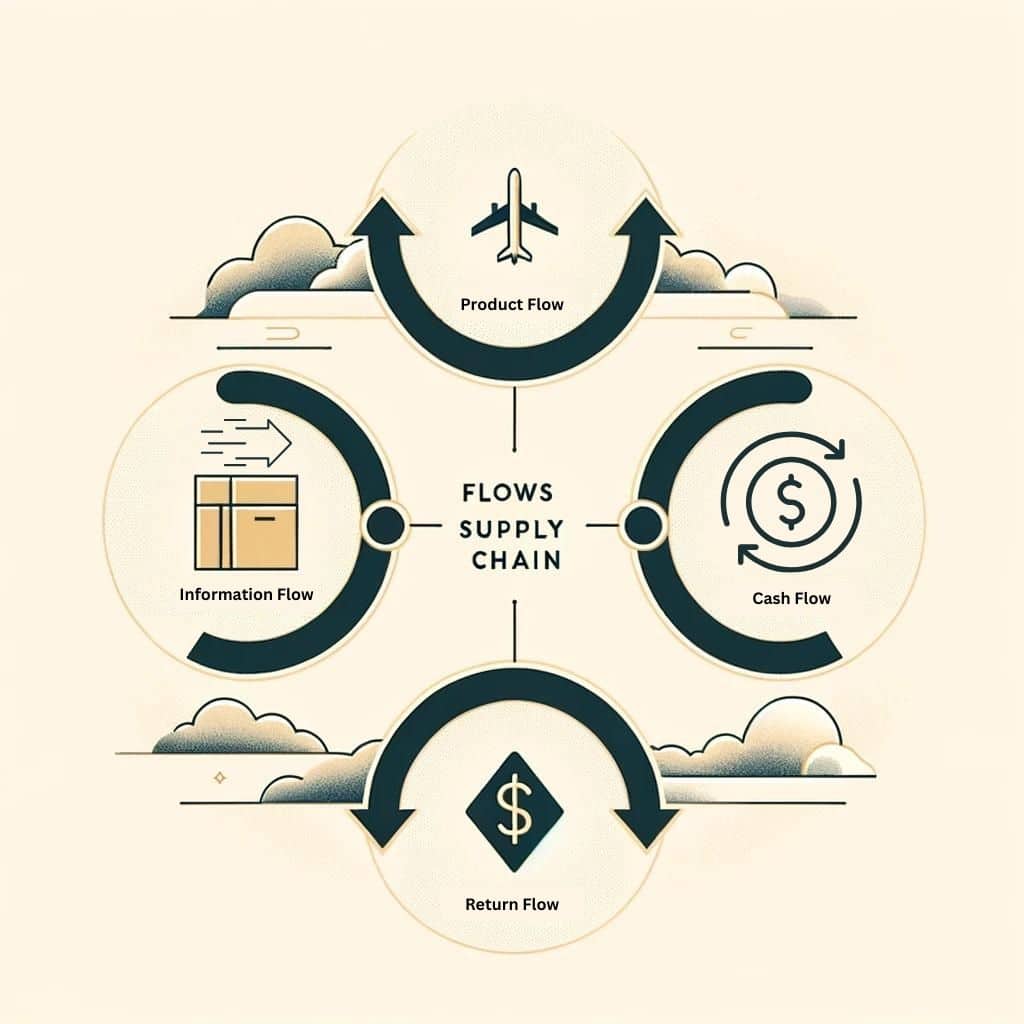

Supply Chain Management, often abbreviated as SCM, transcends beyond the traditional understanding of merely moving goods from one point to another. It represents a symphony of integrated processes, harmonized strategies, and a vision that interlinks every stakeholder in the product’s journey – from raw material sourcing to the final hands of consumers.

One of the core tenets of SCM is the Value Creation. It’s not just about the flow of products, but also the flow of value. As raw materials transform into finished products, they gain value at each stage. Effective SCM ensures this value augmentation is optimized, adding to the profitability and reputation of businesses.

Visibility is another cornerstone. In our age of digital interconnectedness, businesses no longer operate in isolation. A disruption in one part of the world can ripple through supply chains globally. By leveraging technologies such as IoT, blockchain, and cloud computing, SCM can provide real-time visibility into every nook and cranny of the supply chain, offering businesses the foresight to preempt challenges and pivot swiftly.

Collaboration can’t be emphasized enough. Gone are the days when suppliers and manufacturers worked in silos. Today’s SCM champions the cause of collaborative planning, forecasting, and replenishment (CPFR). By synchronizing data and strategies with partners, businesses can reduce inefficiencies, avoid stockouts, and ensure that the right products are available at the right place and time.

Moreover, Risk Management is woven into the fabric of modern SCM. Whether it’s geopolitical tensions, environmental disasters, or global pandemics, today’s supply chains face multifaceted risks. A proactive SCM strategy constantly assesses these vulnerabilities, formulating contingency plans and ensuring business continuity in the face of adversity.

Lastly, as sustainability and ethical considerations take center stage globally, Sustainable SCM is gaining prominence. It’s not just about economic viability anymore. Environmental stewardship, ethical sourcing, and social responsibility are integral parts of the modern supply chain management narrative.

In essence, SCM is evolving, mirroring the complexities and demands of the contemporary business landscape. As companies navigate this intricate maze, a robust SCM strategy stands as their compass, guiding them towards operational excellence, customer satisfaction, and sustainable growth.

Key Performance Indicators (KPIs): The Pillars of Logistics

Ever felt like navigating your business without a compass?

Fear not, for Key Performance Indicators, our team is here to illuminate the murky waters and guide your ship to the golden shores of success!

Here are the 5 most important KPIs to follow :

- On-Time Delivery (OTD): Think of this as the heartbeat of logistics. It’s simple – are your goods reaching their destinations punctually? OTD isn’t just a metric; it’s a promise, a testament to your commitment. Nail this, and you’re not just delivering products, you’re delivering trust.

- Inventory Turnover: Ah, the art of inventory dance! Too much, and you’re hoarding; too little, and you’re, well, out of stock. This KPI tells you how often you’re selling and replenishing your inventory in a given period. Master this groove, and you’re setting the rhythm for a flawless logistical ballet.

- Cost of Freight: This isn’t about scrimping pennies; it’s about optimizing value. Every dollar saved here can be channeled into innovation, customer satisfaction, or perhaps, that swanky new espresso machine for the breakroom!

- Order Accuracy: Ever expected a Hawaiian pizza and got pepperoni instead? Ouch. Ensuring what’s ordered matches what’s delivered is the crux of this KPI. Get this right, and you’re not just delivering goods; you’re delivering happiness.

- Customer Satisfaction: Here’s the golden goblet of KPIs. The applause, the encore, the standing ovation! By gauging feedback and ensuring smiles all around, this metric ensures your logistics isn’t just efficient, it’s legendary!

In the grand theatre of logistics, KPIs are the spotlights, shining down and illuminating the path to stellar performances. When these metrics sing in harmony, they create a symphony of success, turning logistics from a mere function to an art form.

The Dynamic Logistics Industry Landscape:

Buckle up, dear reader, for we’re embarking on a whirlwind tour of the logistics landscape—a world where the only constant is change and every dawn brings forth new challenges and innovations.

Tech Titans’ Entry:

Enter the world where tech giants aren’t just content with ruling the digital realm. Companies like Amazon and Alibaba aren’t merely dabbling; they’re diving deep into logistics. With drones dancing in the skies and robots trotting warehouse floors, they’re reshaping the future of deliveries and distributions.

Green Logistics:

With the world echoing a clarion call for sustainability, the logistics industry is donning the green cape. Electric trucks, biofuels, and optimized routing to reduce carbon footprints are no longer mere buzzwords; they’re the industry’s pledge to Planet Earth.

The E-commerce Explosion:

Click, tap, and voilà! As e-commerce booms, logistics hustles to keep pace. The challenge? Delivering an avalanche of online orders, ensuring that the joy of the virtual cart transforms into real-world delight.

Data, the New Oil:

In the vast logistics terrain, data-driven insights are the modern-day compass. Predictive analytics, AI-powered forecasting, and real-time tracking are ensuring that decisions aren’t just informed; they’re precision-perfect.

Customer Experience is King:

Gone are the days when logistics was a behind-the-scenes player. Now, with real-time tracking, interactive interfaces, and instant feedback loops, it’s stepping into the limelight, ensuring that every package delivered is a customer experience par excellence.

Navigating this dynamic landscape might feel akin to taming a wild stallion at times. Yet, it’s this very dynamism that makes logistics an adrenaline-pumping adventure. As boundaries blur and horizons expand, the logistics industry isn’t merely adapting; it’s pioneering, charting new territories, and setting benchmarks for the world to marvel at.

In the riveting saga of modern commerce, the logistics industry stands tall, not just as a chapter but as a pivotal character, driving the narrative and determining its trajectory.

The Pinnacle of Logistics and Supply Chain Excellence

Logistics performance stands as the bedrock of business success, directly influencing profitability, efficiency, and customer satisfaction. By meticulously evaluating metrics like delivery speed, logistics cost, and inventory management, businesses can pinpoint improvement avenues, ensuring their operations remain agile and customer-centric.

In this digital age, the fusion of automation and analytics heralds the future of logistics. These tools provide deeper insights, streamline operations, and significantly reduce costs. Furthermore, strengthening the supply chain is pivotal. From establishing reliable logistics partnerships to investing in advanced technologies, businesses must prioritize optimizing their supply chain processes for enhanced profitability.

Meanwhile, Supply Chain Management (SCM) emphasizes aligning logistics activities with customer needs and business objectives. It’s a holistic approach, promoting collaboration and ensuring cost-effective operations. Key Performance Indicators (KPIs) serve as the guiding stars in this vast logistical universe, spotlighting essential metrics such as on-time delivery, order accuracy, and customer satisfaction.

Lastly, the ever-evolving logistics landscape demands attention. Tech innovations, sustainability drives, and the e-commerce surge are reshaping the industry, making adaptability and foresight crucial.

In essence, mastering logistics and supply chain management isn’t merely beneficial—it’s imperative for any forward-thinking business, dictating their market relevance, competitiveness, and success.

Recommended Reads:

Managing Raw Materials: Logistics and Classification!

Leveraging Facility Logistics to Optimize Performance

Transportation Operations: 5 Breakthrough Methods

Supply Network Design: The Unsung Hero of Business Success