In the ever-evolving world of business, mastering supply chain dynamics has become a crucial element for achieving competitive advantage and operational excellence. Supply chains are no longer just about logistics and inventory management. They are complex ecosystems that demand strategic planning and execution for effective functioning.

This blog post delves into the heart of supply chain dynamics, offering insightful strategies for businesses looking to enhance efficiency and create significant value in their operations. Whether you’re grappling with the challenges of a global supply network or striving for innovation in your local distribution, the upcoming sections will equip you with essential knowledge and actionable tips to transform your supply chain into a powerhouse of productivity and profitability.

Understanding the Basics of Supply Chain Dynamics

What are Supply Chain Dynamics?

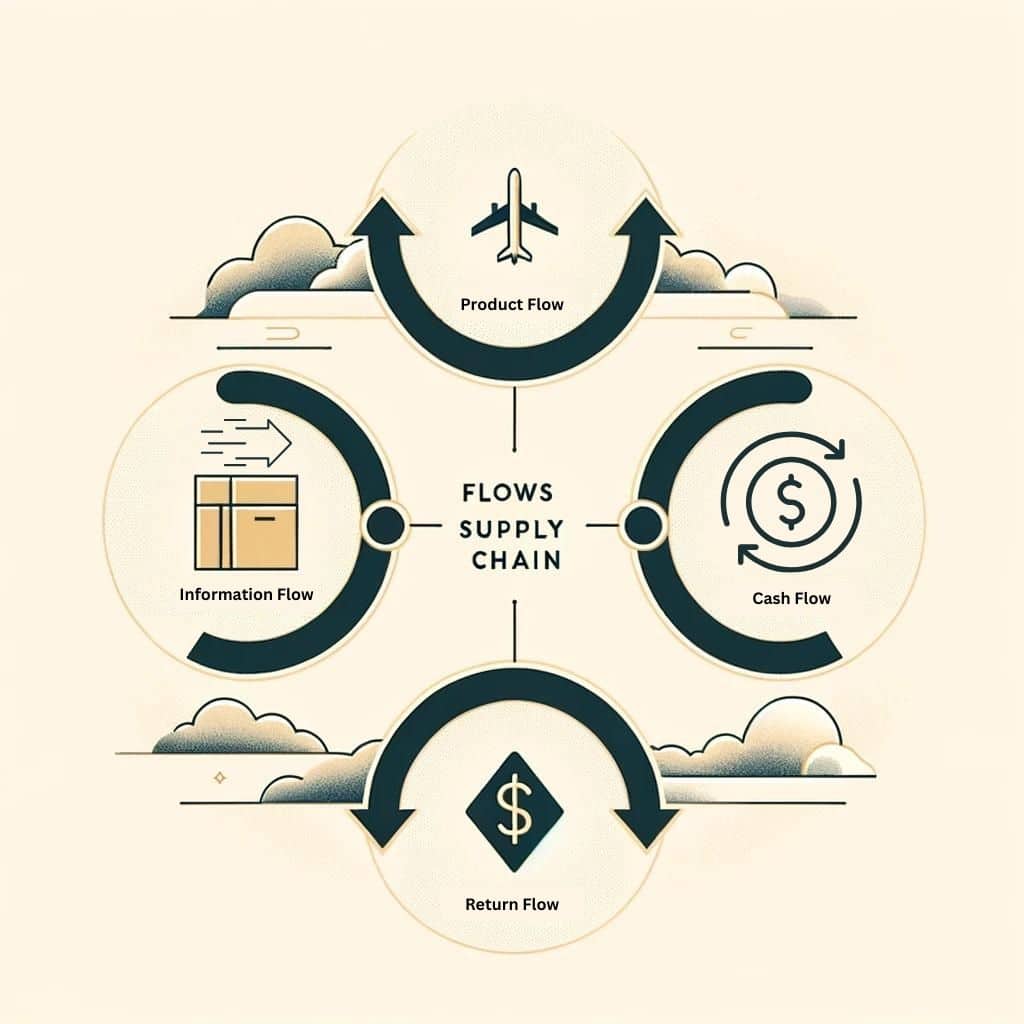

Supply chain dynamics refer to the intricate and often rapidly changing interactions that occur within and between the various elements of a supply chain. These dynamics are influenced by a multitude of factors such as market demand, supplier relationships, production processes, and logistical considerations.

Understanding these dynamics is crucial, as they determine the flow of goods and services from suppliers to end customers. They encompass everything from raw material procurement to product delivery, and each step in this process can significantly impact efficiency, cost, and customer satisfaction.

The Role of Supply Chain Dynamics in Business Performance

The effectiveness of supply chain dynamics is a major determinant of a business’s overall performance. A well-orchestrated supply chain ensures timely production, cost efficiency, and consistent product availability, which are critical for customer satisfaction and business success.

Conversely, inefficiencies in the supply chain can lead to delays, increased costs, and compromised product quality. This can ultimately impact a company’s reputation and its bottom line. Therefore, a keen understanding and proactive management of supply chain dynamics are essential for businesses to thrive in a competitive market.

Key Components of the Supply Chain

- Sourcing: This involves selecting suppliers and managing relationships with them. Effective sourcing ensures a reliable and cost-effective supply of quality raw materials.

- Manufacturing: This is the process of converting raw materials into finished products. Efficient manufacturing requires a seamless integration of various factors like labor, machinery, and technology to meet production targets and quality standards.

- Distribution: This component deals with the transportation of finished goods to retailers or directly to consumers. Effective distribution strategies are critical for minimizing costs and ensuring timely delivery.

- Logistics: Logistics encompasses the overall management of how resources are acquired, stored, and transported to their final destination. It plays a pivotal role in ensuring that the right products reach the right place at the right time.

By mastering these key components, businesses can significantly enhance their supply chain’s efficiency, adaptability, and responsiveness to market changes, driving overall success and customer satisfaction.

Challenges in Modern Supply Chains

Modern supply chains face a myriad of challenges that can significantly impact their efficiency and effectiveness. Understanding these challenges is crucial for businesses to develop robust strategies that can withstand and adapt to these dynamic conditions.

1. Globalization and Its Effects

Globalization has expanded the scope and complexity of supply chains, often spanning multiple countries and continents. This expansion brings challenges like dealing with diverse regulations, cultural differences, and geopolitical risks.

Furthermore, longer supply chains increase the risk of disruptions and complicate logistics and communication, requiring more sophisticated coordination and risk management strategies.

2. Demand Fluctuations and Supply Chain Disruptions

Market demand is more volatile than ever, driven by rapidly changing consumer preferences and global economic conditions. Supply chains must be agile to respond to these fluctuations effectively.

Moreover, disruptions such as natural disasters, pandemics, or political instability can lead to unexpected delays and shortages. Businesses must develop contingency plans and flexible strategies to manage these disruptions and maintain smooth operations.

3. The Impact of Technology and Digital Transformation

While technology offers solutions for many supply chain challenges, its rapid evolution also presents difficulties. Integrating new technologies like AI, blockchain, or IoT requires significant investment, training, and sometimes a complete overhaul of existing processes.

Additionally, cybersecurity becomes a major concern as more supply chain processes become digitized. Keeping pace with technological advancements while ensuring seamless integration and data security is a significant challenge for modern supply chains.

4. Sustainability and Ethical Practices

Consumers and governments are increasingly demanding sustainable and ethical supply chain practices. This includes reducing environmental footprints, ensuring fair labor practices, and ethical sourcing of materials.

Companies face the challenge of aligning their supply chain practices with these expectations without compromising on efficiency or profitability. This often requires innovative approaches to sourcing, production, and distribution, as well as transparent reporting of supply chain practices.

In summary, modern supply chains are complex systems that are influenced by a wide range of factors. Addressing these challenges requires a strategic approach, one that incorporates flexibility, technological integration, and a commitment to sustainability and ethical practices.

Strategies for Enhancing Supply Chain Efficiency

Efficiency in supply chain operations is pivotal for reducing costs, increasing profitability, and ensuring customer satisfaction. Several strategies and techniques have been developed to streamline supply chain operations. Here, we explore some of the most effective ones.

Lean Management and Just-in-Time Inventory

Lean management focuses on minimizing waste within manufacturing systems while maintaining productivity. This approach involves analyzing each step in a supply chain and eliminating anything that does not add value. Just-in-Time (JIT) inventory, a key element of lean management, involves keeping stock levels as low as possible. This means products are manufactured or replenished only as needed, reducing storage costs and minimizing the risk of excess inventory.

Embracing Technological Advances

- Artificial Intelligence (AI): AI can forecast demand more accurately, optimize routing and logistics, and improve inventory management through predictive analytics.

- Internet of Things (IoT): IoT devices enable real-time tracking of goods and assets, providing valuable data to optimize routes, reduce delays, and maintain the integrity of perishable items.

- Blockchain: This technology can enhance transparency and security in the supply chain. It provides an immutable ledger, which is ideal for tracking product origin, authenticity, and compliance with environmental and ethical standards.

Case Studies and Examples

- Deere & Company: Facing challenges with a diverse product range and highly seasonal retail activity, Deere & Company initiated a program to reduce supply chain costs by 10% within four years. They redesigned their supply chain network, establishing intermediate merge centers and optimizing cross-dock terminal locations. This reorganization, along with consolidating shipments and increasing the use of third-party logistics providers, led to a $1 billion reduction in inventory, halved customer delivery lead times, and achieved annual transportation cost savings of about 5%. (Trans.info, 2020)

- Intel: Intel encountered a significant challenge in reducing the supply chain costs of its low-cost Atom chip. The company adopted a make-to-order strategy, unusual for the semiconductor industry, and implemented several improvements like reducing the chip assembly test window and moving to a vendor-managed inventory model. These changes brought the order cycle time down from nine weeks to just two, resulting in a cost reduction of more than $4 per unit for the Atom chip, a substantial decrease from the original cost of $5.50 per unit. (Trans.info, 2020)

- Starbucks: Starbucks underwent a period of supply chain challenges, with rising costs and performance issues. They embarked on a transformation program with objectives to reorganize the supply chain, reduce cost to serve, and lay the groundwork for future capabilities. This involved dividing the supply chain into plan, make, and deliver segments, opening a new production facility, and streamlining partnerships with third-party logistics providers. As a result, Starbucks saved over $500 million in 2009 and 2010, with a significant portion of these savings coming from supply chain improvements. (Trans.info, 2020)

These examples demonstrate how diverse strategies, including network redesign, technological innovations, and restructuring of supply chain processes, can lead to significant efficiency improvements and cost savings.

Creating Value in the Supply Chain

Strategies for Supply Chain Innovations

Creating value in the supply chain goes beyond cost reduction and efficiency enhancement. Innovative strategies can add significant value to products or services.

This includes implementing advanced technologies like AI for better demand forecasting, using sustainable and ethical sourcing practices to enhance brand value, or adopting flexible manufacturing techniques to customize products.

These innovations not only improve the product quality but also contribute to building a stronger, more resilient brand.

Customer-Focused Supply Chain Strategies

A customer-centric approach in supply chain management is crucial for adding value. This involves understanding customer needs and expectations and then aligning the supply chain to meet these requirements effectively.

Strategies like improving delivery times, ensuring product availability, and providing transparency in the sourcing and manufacturing processes can greatly enhance customer satisfaction and loyalty. By putting the customer at the heart of the supply chain, companies can create a competitive edge in the market.

Measuring and Maximizing Value Creation

Measuring value creation in the supply chain is vital for continuous improvement. Key performance indicators (KPIs) such as customer satisfaction scores, delivery time accuracy, and product quality rates are essential metrics. Regularly monitoring these KPIs helps in identifying areas for improvement.

Additionally, customer feedback can be a valuable tool for assessing the perceived value and making necessary adjustments. To maximize value creation, companies should focus on continuous innovation, maintaining a balance between cost and quality, and fostering strong relationships with suppliers and partners.

In this section, the focus is on how to add and measure value in the supply chain through innovative strategies, a customer-focused approach, and effective metrics. These elements are crucial for businesses to not only thrive in the current market but also to build a sustainable model for the future.

Navigating the Future of Supply Chain Management

Future Trends in Supply Chain Management

The future of supply chain management is poised to be shaped by several key trends. These include increased automation through robotics and AI, greater emphasis on sustainability and ethical sourcing, and the continued rise of e-commerce which demands more agile and customer-centric supply chains.

Additionally, the integration of advanced technologies like blockchain for transparency and IoT for enhanced connectivity will play a significant role.

Preparing and Adapting to Future Changes

To stay ahead, businesses must be proactive in adapting to these changes. This involves investing in new technologies, re-evaluating supply chain strategies in light of emerging trends, and remaining flexible to pivot as market conditions change.

Building a digitally skilled workforce and fostering a culture of innovation will be crucial for companies to thrive in this evolving landscape.

The Importance of Continuous Learning

The field of supply chain management is constantly evolving, making continuous learning and staying informed essential. This can be achieved through ongoing training programs, attending industry conferences, and staying updated with the latest research and case studies.

Embracing a mindset of lifelong learning will enable professionals and organizations alike to remain competitive and efficient in the face of future supply chain challenges.

In this section, the focus is on the evolving nature of supply chain management, highlighting future trends, the need for adaptability and preparation, and the importance of continuous learning to successfully navigate upcoming changes in the field.

Conclusion

In this blog, we’ve explored the intricacies of supply chain dynamics, covering the basics, challenges in modern supply chains, strategies for efficiency, ways to create value and future trends. The key to thriving in this ever-evolving domain lies in understanding these dynamics, leveraging technology, focusing on customer-centric approaches, and constantly adapting to new trends.