In the world of commerce, the efficiency and robustness of supply chain management cannot be overstated. It is the silent engine behind the scenes, ensuring that goods move seamlessly from production lines to the hands of consumers worldwide.

Understanding the complexities of this process, including the pivotal role played by the four fundamental flows—product, information, cash, and returns—is crucial for businesses aiming to thrive in today’s fast-paced market.

To gain further insight into how these elements contribute to the movement of goods from raw materials to retail shelves, I recommend reading our detailed exploration in “From Raw to Retail: The Flow of Goods“.

This piece provides a comprehensive background, setting the stage for a deeper dive into the specifics of supply chain management’s critical flows.

What Do We Mean by Flow of Goods?

The “flow of goods” refers to the movement of products from their initial production phase through to their final delivery to consumers.

This concept is a cornerstone of supply chain management, highlighting the journey products take from raw materials to finished goods ready for sale.

Understanding this flow is critical for businesses as it directly impacts efficiency, cost management, and customer satisfaction.

By optimizing the flow of goods, companies can ensure timely delivery, minimize expenses, and meet consumer demands effectively, thus playing a pivotal role in the overall success of supply chain operations.

Enhancing your business’s overall performance and optimizing the flow of goods can significantly benefit from implementing Value Stream Mapping (VSM). This method is highly effective for streamlining processes and improving efficiency.

For additional insights and a practical example of how to apply VSM, I suggest visiting our detailed section “Mapping Your Flow” in the article “From Raw to Retail: The Flow of Goods.” This resource offers a focused look at employing VSM to better manage and understand the flow of goods within your operations.

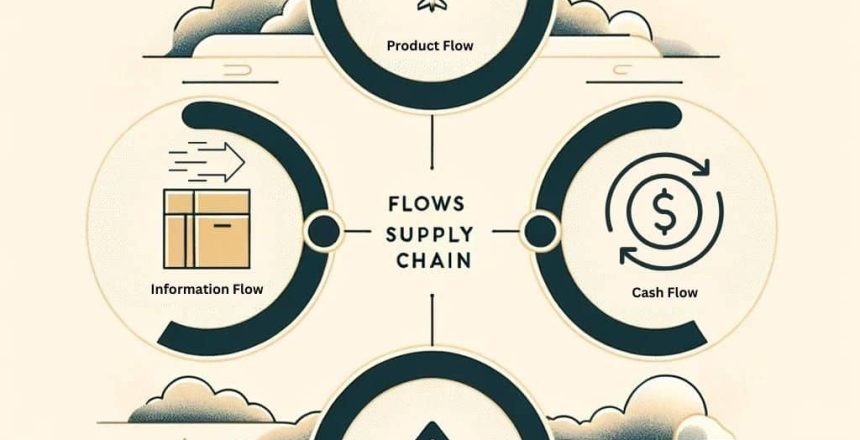

The Four Pillars of Supply Chain Flow

Understanding the intricate components that drive the efficiency and responsiveness of modern supply chains is crucial for businesses aiming to stay competitive.

The supply chain is a complex system, requiring coordination across various stages to ensure products reach the end consumer effectively and efficiently.

This system is built on four foundational pillars: Product Flow, Information Flow, Cash Flow, and Return Flow. Each of these pillars plays a vital role in the supply chain, affecting everything from inventory management to customer satisfaction.

This exploration is based on insights from multiple sources, which highlight the significance and operational strategies within each pillar.

- https://scmwizard.com/supply-chain/

- https://www.toppr.com/guides/business-environment/business-functions/supply-chain/

- https://corporatefinanceinstitute.com/resources/management/supply-chain/

- https://cscmp.org/CSCMP/Develop/Starting_Your_Career/Importance_of_Supply_Chain_Management.aspx

1. Product Flow

The product flow pillar focuses on the movement of goods from suppliers through to consumers, including the return processes. It’s the physical manifestation of the supply chain, tracing the path of products from production, through distribution, to retail, and finally to the customer.

This flow is crucial for maintaining low inventory levels, ensuring quality, and minimizing production of defective products. An example of efficiency in product flow can be seen in Dell’s supply chain, where low inventory levels and direct customer feedback mechanisms allow for immediate response to issues, thereby reducing waste and increasing customer satisfaction.

2. Information Flow

The information flow encompasses the transmission of orders and the updates on delivery status. It’s underpinned by the use of sophisticated software systems and web-based applications that enhance supply chain management by enabling data sharing both internally and with external partners.

This flow ensures that all parties, from suppliers to customers, have access to real-time data, facilitating better decision-making, improving time-to-market, and enhancing cost efficiency. The integration and coordination of information flow are pivotal for optimizing resources and meeting customer demands efficiently.

3. Cash Flow

Cash flow within the supply chain involves the financial transactions between all parties, from suppliers to consumers. Efficient cash flow management ensures that companies can collect from customers promptly while managing payables to suppliers, optimizing their financial resources.

This financial aspect is critical for maintaining a healthy balance sheet and ensuring the supply chain’s economic sustainability. Effective cash flow management can lead to significant savings and improved profit margins for firms across the supply chain.

4. Return Flow

Handling returns and recalls efficiently is vital for maintaining customer satisfaction and trust. The return flow involves strategies for managing the return of goods from consumers back to retailers or manufacturers for refunds, replacements, or recycling. Efficiently managing this flow reduces costs and waste, while also providing valuable feedback for improving product quality and supply chain processes. This aspect of supply chain management emphasizes the importance of agility and adaptability in responding to customer needs and market demands.

Together, these four pillars form the foundation of a resilient and responsive supply chain, essential for meeting customer expectations and achieving business success. Supply chain management’s complexity requires a deep understanding of these flows and the adoption of strategies that optimize these interconnected components.

The Journey of Goods in the Supply Chain: From Raw Materials to Customers

The supply chain’s essence lies in its ability to move goods from the initial point of raw materials to the final point of consumption. This journey is both complex and meticulously structured, ensuring that products reach consumers efficiently and satisfactorily.

Let’s explore the step-by-step process, along with the challenges that arise and the solutions devised to overcome them.

Step-by-Step Explanation of the Process

- Sourcing of Raw Materials: The supply chain begins with the extraction or production of raw materials. These are the fundamental components needed to manufacture products, ranging from metals and minerals to textiles and ingredients.

- Manufacturing and Production: Raw materials are then transported to manufacturing facilities, where they are processed and assembled into finished goods. This stage involves various processes and machinery, transforming inputs into products ready for the market.

- Quality Assurance and Testing: Before leaving the factory, products undergo quality control checks to ensure they meet the required standards. This step is crucial for maintaining brand reputation and customer satisfaction.

- Warehousing and Inventory Management: Manufactured goods are moved to warehouses where they are stored until needed. Effective inventory management strategies are employed to balance supply and demand, minimizing holding costs while ensuring product availability.

- Distribution and Logistics: Goods are then distributed to retail outlets or directly to consumers through logistics networks. This involves transportation via road, rail, sea, or air, depending on the product type and destination.

- Retail and Sales: In the retail phase, products are made available for purchase through various channels, including brick-and-mortar stores and online platforms. Retailers play a crucial role in marketing the products, influencing consumer decisions.

- After-Sales Support and Services: The journey concludes with after-sales services, including customer support, warranties, and returns. This phase is essential for building customer loyalty and facilitating repeat business.

Challenges and Solutions

The supply chain faces numerous challenges, from production delays and transportation disruptions to inventory mismanagement and changing consumer demands. Solutions to these challenges often involve a combination of technology, strategic planning, and collaboration.

- Production Delays: Implementing lean manufacturing techniques and maintaining strong supplier relationships can minimize delays.

- Transportation Disruptions: Diversifying transportation modes and routes ensures that goods can be rerouted quickly in case of disruptions.

- Inventory Mismanagement: Advanced inventory management systems that use real-time data help in accurately forecasting demand and adjusting supply levels accordingly.

- Changing Consumer Demands: Flexibility and adaptability are key. Companies should stay attuned to market trends and be ready to pivot their strategies to meet evolving consumer preferences.

Overcoming these hurdles requires a proactive approach, leveraging technology, and fostering strong partnerships throughout the supply chain. By addressing these challenges head-on, companies can ensure a smooth journey for goods from raw materials to customers, ultimately achieving operational excellence and customer satisfaction.

Delivering Value to Customers: Meeting Customer Expectations

The core objective of any supply chain is not just to deliver products, but to deliver value to the end customer. This entails not only meeting but exceeding customer expectations through efficient supply chain management. Let’s explore how supply chain efficiency impacts customer satisfaction and examine some real-world case studies of successful supply chain management.

How Supply Chain Efficiency Impacts Customer Satisfaction

Supply chain efficiency directly correlates with customer satisfaction in several key areas:

- Timeliness: Efficient supply chains ensure products are delivered within the expected delivery window, which is crucial for customer satisfaction. Delays can lead to dissatisfaction and potentially lost sales.

- Product Quality and Availability: A well-managed supply chain ensures that products are not only of high quality but also readily available when customers need them. Stockouts can frustrate customers and drive them to competitors.

- Transparency and Communication: Today’s customers expect to be informed about their order status from placement through to delivery. Efficient supply chains use technology to provide real-time updates and transparency, enhancing customer trust and loyalty.

- Cost-Effectiveness: Efficiency in the supply chain can lower operational costs, savings that can be passed on to customers through competitive pricing, further increasing satisfaction and loyalty.

Case Studies: Real-world Examples of Successful Supply Chain Management

- Amazon: Amazon’s supply chain is a benchmark in supply chain efficiency, using advanced technology and an extensive logistics network to offer same-day or next-day delivery on thousands of items. Its customer-centric approach, with features like real-time tracking and easy returns, sets a high standard for customer satisfaction.

- Zara: The fashion retailer Zara is known for its ability to bring new products to market in just a few weeks. Its supply chain is optimized for speed, with tight control over every aspect from design to distribution. This allows Zara to respond quickly to fashion trends and customer demand, ensuring high levels of customer satisfaction.

- Dell: Dell revolutionized the PC market with its build-to-order model, allowing customers to customize their computers. This was supported by a highly efficient supply chain that minimized inventory costs and enabled quick assembly and delivery of custom orders, leading to high customer satisfaction and loyalty.

- Toyota: Toyota’s “Just-In-Time” (JIT) manufacturing process is a cornerstone of its supply chain efficiency. By producing goods only as they are needed, Toyota minimizes waste and reduces inventory costs. This approach not only streamlines the supply chain but also ensures that customers receive high-quality vehicles in a timely manner.

These case studies highlight how integral supply chain management is to delivering customer value. By focusing on efficiency, transparency, and responsiveness, companies can build a competitive advantage that translates into higher customer satisfaction and loyalty.

Innovations in Supply Chain Flows: Emerging Technologies and Sustainability

The landscape of supply chain management is continuously evolving, with innovations aimed at improving efficiency, transparency, and sustainability. Emerging technologies such as Artificial Intelligence (AI), the Internet of Things (IoT), and blockchain are at the forefront of this transformation, while the push for sustainability and ethical practices is reshaping the supply chain’s environmental impact.

Emerging Technologies

- Artificial Intelligence (AI): AI is revolutionizing supply chain management by enhancing decision-making processes, demand forecasting, and customer service. Through machine learning algorithms, AI can predict market trends, optimize inventory levels, and automate routine tasks, leading to increased efficiency and reduced operational costs.

- Internet of Things (IoT): IoT technology enables real-time tracking of goods and assets throughout the supply chain. Sensors and connected devices provide valuable data on the condition, location, and movement of products, allowing for greater visibility, improved asset utilization, and proactive management of potential issues.

- Blockchain: Blockchain technology offers a secure and transparent way to document transactions within the supply chain. By enabling immutable records of product origin, handling, and ownership, blockchain enhances traceability, reduces fraud, and facilitates trust among supply chain participants.

Sustainability and Ethical Practices

The emphasis on sustainability and ethical practices within the supply chain is growing, driven by consumer demand and regulatory pressures. Incorporating green practices into supply chain management not only benefits the environment but also enhances brand reputation and can lead to cost savings.

- Eco-friendly Materials and Processes: Choosing sustainable materials and eco-friendly manufacturing processes reduces the environmental impact of products. Companies are increasingly adopting circular economy principles, focusing on the reuse and recycling of materials to minimize waste.

- Energy-efficient Logistics: Optimizing transportation routes and using energy-efficient vehicles help reduce carbon emissions associated with logistics. Many companies are also exploring alternative fuels and electric vehicles as part of their commitment to sustainability.

- Ethical Sourcing: Ethical sourcing ensures that products are obtained in a responsible and sustainable way, respecting the environment and human rights. Companies are increasingly transparent about their sourcing practices, working closely with suppliers to ensure adherence to ethical standards.

- Sustainable Packaging: Reducing packaging waste through the use of recyclable materials and minimal packaging designs is another aspect of sustainable supply chain practices. Innovations in packaging technology are helping companies to achieve this goal while still protecting their products.

These innovations and practices are not only transforming the supply chain from a technical and operational standpoint but are also redefining the ethical and environmental responsibilities of businesses. As companies continue to adopt these technologies and practices, the supply chain becomes not just a mechanism for delivering products, but a platform for promoting sustainability and driving positive change.

Conclusion: Navigating the Future of Supply Chain Management

The exploration of the supply chain’s four foundational pillars—Product Flow, Information Flow, Cash Flow, and Return Flow—alongside the journey of goods from raw materials to customers, and the impact of emerging technologies and sustainability practices, offers a comprehensive overview of the complexities and dynamics shaping supply chain management today.

Summary of Key Points

- Efficiency and Responsiveness: The efficient and responsive management of product, information, cash, and return flows is crucial for meeting consumer demands and driving business success.

- Innovations: Emerging technologies like AI, IoT, and blockchain are revolutionizing the supply chain, enhancing transparency, efficiency, and security.

- Sustainability and Ethics: Incorporating green practices and ethical sourcing into supply chain management is increasingly important, driven by consumer expectations and regulatory standards.

The Future of Supply Chain Management

Looking ahead, the future of supply chain management is poised for significant transformation. Technological advancements will continue to play a pivotal role, further automating processes and providing even greater data insights for strategic decision-making. The integration of AI and IoT technologies will become more refined, offering unprecedented levels of visibility and control over supply chain operations.

Sustainability will move from being a competitive advantage to a business imperative, as companies increasingly prioritize reducing their environmental impact and ensuring ethical practices throughout their supply chain. This shift will not only help in addressing global environmental challenges but also meet the growing demand for transparency and sustainability from consumers.

Moreover, the future will likely see a greater emphasis on resilience and agility in supply chain strategies. The recent global challenges have highlighted the importance of being able to quickly adapt and respond to disruptions. Businesses will invest more in predictive analytics and flexible supply chain models to navigate uncertainties and maintain continuity in the face of unforeseen events.

In conclusion, as we look towards the future, the supply chain will become more integrated, intelligent, and sustainable, underpinning the operational success of businesses and the wider economy. The companies that embrace these changes, investing in technology and sustainability, will be well-placed to lead in their markets, delivering value not only to their customers but to society as a whole.