What is Facility Logistics?

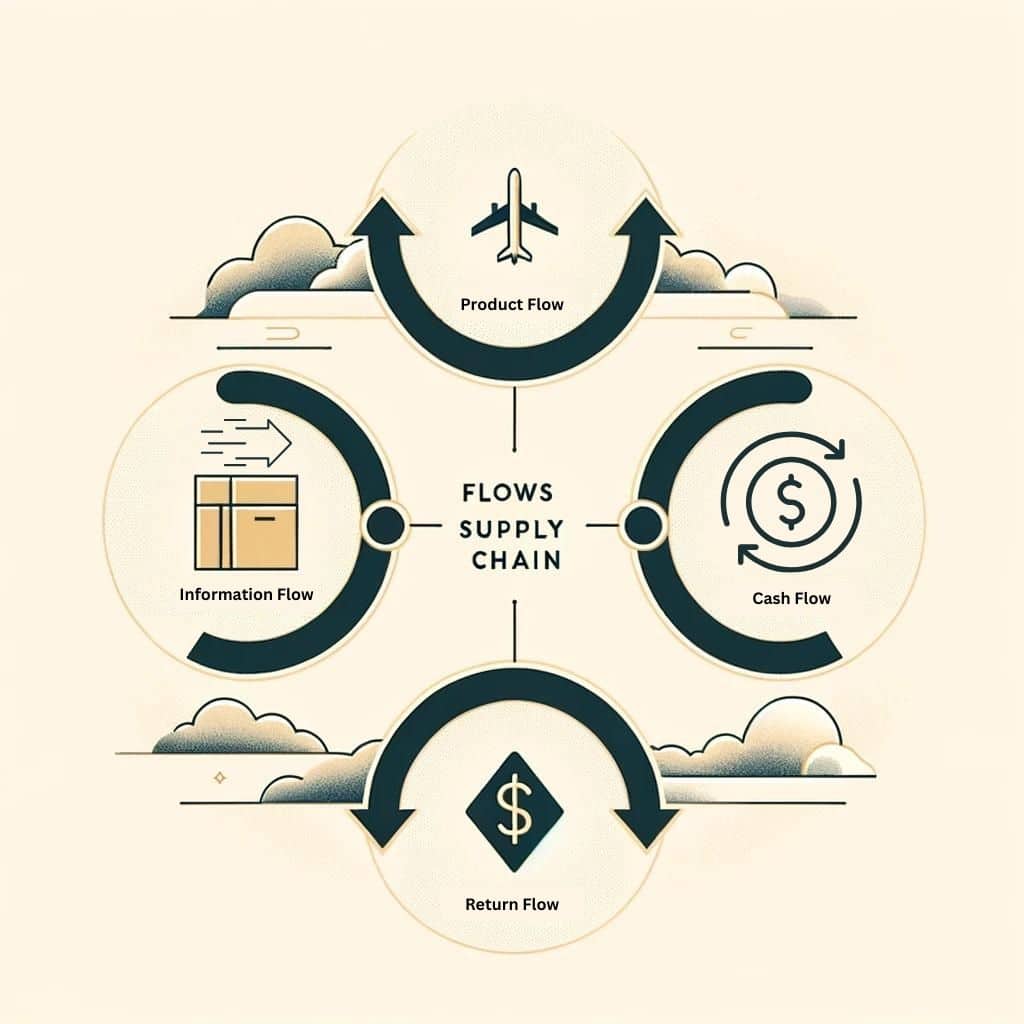

Facility Logistics is an overarching term for the range of services, solutions, and processes needed to support the effective flow of goods through a supply chain. It involves managing inventory in warehouses, optimizing transportation routes, and scheduling deliveries, as well as ensuring that there is sufficient storage capacity available at each facility.

Facility logistics also encompass other related functions such as inventory management, order fulfillment, and customer service.

It plays a vital role in helping companies get their products to customers quickly and efficiently.

Streamlining processes within a supply chain can help reduce costs associated with delays caused by inefficient delivery methods or inadequate facilities.

It also helps companies increase efficiency by reducing waste and increasing production speed.

Ultimately, facility logistics helps create an efficient system that allows businesses to operate at peak efficiency and provide customers with the best service possible.

Facility logistics also encompasses the implementation of strategies such as lean manufacturing, six sigma, and ISO 9000 to optimize processes within a supply chain.

By implementing these strategies, companies can identify areas of waste or inefficiency and make necessary changes to increase productivity and reduce costs.

Facility logistics also includes the use of technology such as warehouse management systems (WMS) to reduce labor costs and improve accuracy in order fulfillment.

It is essential for companies looking to operate at peak efficiency, maximize profits and stay competitive in today’s market.

Facility logistics can also involve using alternative methods of transportation such as air freight and sea freight to minimize costs associated with transportation.

By utilizing alternative methods, companies can reduce the cost of delivery and improve customer service.

In this blog post, you will also learn how it encompasses cross-docking and consolidation centers which can reduce the time it takes for goods to reach their destination, thus increasing efficiency.

Facility logistics is an essential component of a successful supply chain and is essential for companies looking to stay competitive in today’s market.

Let’s look at the types of logistics facilities.

What are the Types of Logistics Facilities?

Logistics facilities can be divided into three main categories: warehouses, transportation hubs, and fulfillment centers.

Warehouses are primarily used for storing goods before shipment.

Transportation hubs are ideal for receiving, sorting, and consolidating freight before delivery, while fulfillment centers provide a range of services including order processing, order picking, and packing.

Facility logistics also encompasses other related functions such as inventory management, customer service, and order tracking.

Also, it’s an essential component of any successful supply chain and can help improve efficiency, reduce costs and increase customer satisfaction. Facility logistics is an important part of a successful business that helps ensure products reach customers quickly and efficiently.

It can also involve using alternative methods of transportation such as air freight or sea freight to minimize.

Warehouse Management Systems

Warehouse Management Systems enable companies to increase their efficiency by automating processes such as inventory tracking, order fulfillment, shipment processing/tracking, and more.

They also offer real-time data on all activities taking place inside a warehouse and help streamline operations while improving accuracy and visibility into the supply chain process.

By leveraging Warehouse Management Software solutions, businesses can optimize their resources resulting in improved profitability and customer satisfaction.

Warehouse Management Systems empower businesses to better manage their warehouses with enhanced capabilities including dynamic.

Transportation Hubs

Transportation hubs are used to receive and sort freight before delivery. This allows companies to consolidate shipments, reduce transportation costs, and improve customer service.

These facilities also help streamline the shipping process by utilizing automated systems such as RFID tags or tracking labels.

Facility logistics can also involve using alternative methods of transportation such as air freight or sea freight to minimize delivery time while keeping operating costs down.

Transportation hubs are essential for companies looking to stay competitive by ensuring that goods reach their destination quickly and efficiently.

In conclusion, facility logistics is an important part of any successful supply chain and can help improve efficiency, reduce costs and increase customer satisfaction. By utilizing warehouse management systems, transportation hubs, and alternative methods of transportation, companies can maximize profits while staying competitive in today’s market.

Fulfillment Centers

Fulfillment centers provide a wide range of services including order processing, order picking and packing, inventory management, and customer service assistance.

Facility logistics helps ensure products reach customers quickly and efficiently through these services. By integrating new technologies such as artificial intelligence (AI) and machine learning (ML), fulfillment centers can reduce the time it takes for goods to reach their destination, thus increasing efficiency and customer satisfaction.

Facility logistics is an essential part of any successful supply chain and helps to keep businesses competitive in today’s market.

By leveraging Facility Logistics solutions companies can streamline operations, improve accuracy, reduce costs and provide improved customer service. Facility Logistics enables companies to remain competitive by optimizing their resources resulting in improved profitability and customer satisfaction.

Facility logistics is an important component of a successful business that helps ensure products reach customers quickly and efficiently.

What are distribution centers?

Distribution Centers are typically located at strategic points within a region or country for maximum efficiency and cost savings.

Warehouses are used for the storage of goods and products. They are used by businesses to receive, store, and redistribute products from various sources.

Distribution Centers are essential in providing goods and services to customers quickly and efficiently.

By using distribution centers, businesses can reduce transportation costs while maximizing their reach across multiple markets.

It provides many benefits to businesses such as faster order processing times, improved customer service response time, better utilization of resources, reduced labor costs, increased sales volumes due to enhanced access to different regions, and improved inventory management.

Distribution centers serve as a hub for the flow of goods, products, and services across multiple locations.

What are Cross-Docking Facilities?

Cross-Docking is a logistics process whereby goods are unloaded from inbound delivery vehicles and loaded into outbound delivery vehicles with minimal handling and storage.

It plays an important role in supply chain management, as they enable faster freight turnover, improved inventory control, streamlined transportation costs, and better customer service.

Cross-Docking facilities typically include loading docks, staging areas, and sorting areas where goods are unloaded from inbound vehicles, sorted by destination, and then loaded into outbound vehicles.

Let’s look at the major benefits of Cross-Docking facilities :

- Used to reduce costs associated with warehousing, inventory management, and distribution processes

- It helps reduce the time required for a product to move through the supply chain and provides greater flexibility to adapt to changes in demand

- It reduces the amount of inventory stored in a warehouse, as goods can be transferred from one vehicle to another without being stored

- Reduces storage costs and improves the speed of goods delivery

- Enables businesses to respond quickly to customer requests and changes in demand

- Provides businesses with a cost-effective way of managing their supply chain

Truck terminals serve a similar purpose as Cross-Docking facilities but on a larger scale. They are designed to facilitate truck freight transportation and storage of truck freight.

Truck terminals are generally much larger than Cross-Docking facilities and often involve trucking companies, truck mechanics, truck fuel and truck wash services, truck weighing stations, truck scales, truck parking areas, and truck servicing.

Let’s look at truck terminals in detail.

What are truck terminals?

Truck terminals are trucking hubs that serve as a place for truckers to load and unload the freight.

Typically located near major highways, truck terminals provide truckers with easy access to the goods they need while enabling businesses to move their products efficiently around the country.

Truck terminals also typically include services such as :

- On-site mechanics;

- Fuel pumps;

- Truck washes;

- Repair shops;

- Scales;

- Layover areas

These services are provided to support truckers during their routes across the country. By providing these services and conveniences, truck terminals make it easier for truckers to do their job more safely and efficiently.

Additionally, truck terminals help reduce congestion on roads by allowing drivers to get what they need close at hand rather than having to search for resources at locations further away.

In summary, truck terminals are trucking hubs that provide truckers with a variety of services and conveniences. These truck terminals help truckers do their job more safely and efficiently while reducing traffic on roads by providing resources nearby.

What are intermodal terminals?

Intermodal terminals are facilities that allow intermodal freight transport, the movement of goods between different modes of transportation such as rail and truck.

These terminals offer the flexibility to move containers or trailers over long distances by combining two or more modes of transportation.

Intermodal terminals have become an essential part of the global supply chain, providing efficient and cost-effective solutions for moving goods across international borders.

By making use of intermodal technology, companies can optimize their shipping process while saving time, money, and energy.

Additionally, intermodal terminals provide safe and secure storage for freight containers and trailers during transit, ensuring that cargo is not damaged in transit.

With the increasing need for faster and more reliable ways to transport goods around the world, intermodal terminals have become invaluable assets in the global logistics industry.

Conclusion

In conclusion, truck terminals and intermodal terminals are essential components of the global supply chain, providing businesses with a cost-effective way to move goods around the world.

By combining trucking, rail, and other modes of transportation, these facilities make it possible for businesses to respond quickly and efficiently to customer requests while saving time and money.

With an ever-increasing demand for faster and more reliable transportation solutions, truck terminals and intermodal terminals are sure to remain a key part of the global logistics industry.

Managing a facility will always need a lot of effort in managing different sources of innovation to get a competitive edge.