What are Warehouse Management Systems?

Warehouse Management Systems (WMS) are designed to control and manage the receiving, storage, and shipping of products in a business.

WMS are specialized software applications that provide support for the day-to-day operations within a warehouse.

Warehouse Management Systems enable companies to increase their efficiency by automating processes such as inventory tracking, order fulfillment, shipment processing/tracking, and more.

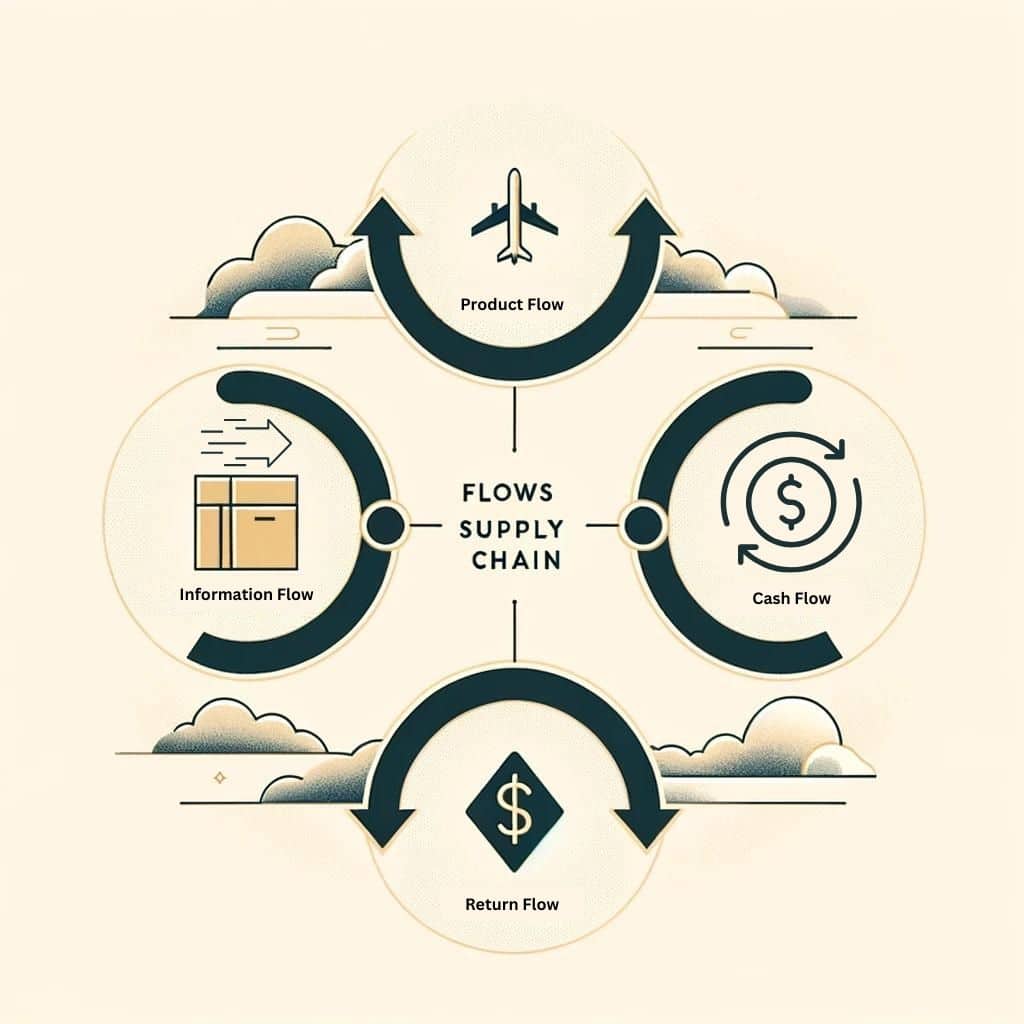

They also offer real-time data on all activities taking place inside a warehouse and help streamline operations while improving accuracy and visibility into the supply chain process.

By leveraging Warehouse Management Software solutions, businesses can optimize their resources resulting in improved profitability and customer satisfaction.

WMS empowers businesses to better manage their warehouses with enhanced capabilities including dynamic.

What are the Types of Warehouse Management Systems?

Warehouse Management Systems can be categorized into two types – Warehouse Execution System (WES) and Warehouse Control System (WCS).

- Warehouse Execution Systems provide the ability to manage, control, and track all production, storage, and distribution activity throughout a warehouse. Warehouse Execution System solutions allow users to improve order accuracy by providing real-time visibility into inventory levels across multiple locations while leveraging advanced functions such as automated material replenishment and cycle counting.

- Warehouse Control System solutions provide businesses with enhanced capabilities including dynamic routing optimization for faster order processing times. Warehouse Control System enables organizations to coordinate and monitor orders in real time while optimizing the use of resources such as labor, materials, equipment, and space.

Example of Warehouse Management Systems

Warehouse Management Systems can be used for a variety of tasks including tracking and managing inventory, streamlining processes such as order fulfillment, shipment processing/tracking, and more.

For example, Warehouse Management Systems can be used to automate processes such as :

- Receiving goods;

- Managing inventory levels;

- Picking and packing orders;

- Shipping goods

Warehouse management systems also allow users to track inbound/outbound shipments, real-time access data on all activities taking place inside a warehouse, and run reports on inventory movements. Warehouse Management Systems enable businesses to improve their efficiency while increasing customer satisfaction.

How do I Optimize my Warehouse Capacity?

As we’ve mentioned earlier, warehouse management systems enable businesses to increase order accuracy and reduce costs

Optimizing your warehouse capacity can be achieved by implementing Warehouse Management System solutions.

Warehouse Management Systems enable companies to streamline operations while improving accuracy and visibility into the supply chain process.

By leveraging Warehouse Management Software solutions, businesses can optimize their resources resulting in improved profitability and customer satisfaction.

Warehouse Management Systems empower businesses to better manage their warehouses with enhanced capabilities.

What are the Basic Functions of a Warehouse?

The basic functions of a Warehouse Management System include, but are not limited to:

- Order Fulfillment: Automate the process of picking, packing, and shipping orders

- Warehouse Organization: Monitor inventory levels and optimize the use of warehouse space

- Shipment Tracking: Track inbound/outbound shipments and manage freight costs

- Real-time Data: Access real-time data on all activities taking place inside a warehouse

- Warehouse Automation: Optimize the use of resources such as labor, materials, equipment, and space

Now let’s see these basic functions in detail.

Order Fulfillment

Streamline the process of selecting, packing, and shipping orders to guarantee on-time delivery with precision.

With Order Fulfillment solutions, companies can experience a drastic transformation in the efficiency of their operations while increasing customer satisfaction.

Warehouse Management System solutions provide businesses with the ability to track orders from the moment they are placed until they are delivered. Order Fulfillment solutions also enable companies to coordinate orders, optimize the use of resources, and monitor shipment performance.

WMS are essential for companies looking to increase order accuracy, reduce costs, and improve customer satisfaction. Order Fulfillment solutions provide businesses with enhanced capabilities for managing the entire fulfillment process.

Order Fulfillment solutions enable businesses to seamlessly manage the entire process from inventory management to pick/pack tasks and material replenishment. It also allows businesses to track orders in real-time and monitor order processing times.

Implementing Order Fulfillment solutions help businesses increase efficiency while decreasing costs.

Warehouse Organization

Warehouse organization is essential for providing efficient and accurate operations.

A Warehouse Management System can help manage inventory levels, optimize the use of warehouse space and improve the accuracy of order fulfillment.

With Warehouse Organization solutions, businesses can assign specific locations to each unit of inventory, optimize the layout of pick/pack areas and identify potential sources of errors.

These solutions enable businesses to optimize the use of their resources, resulting in increased profitability and customer satisfaction.

WMS solutions enable companies to manage inventory levels in real-time and provide visibility into the entire supply chain process.

Shipment Tracking

To satisfy customer requirements, businesses must have the capability to track inbound/outbound shipments.

Shipment Tracking solutions enable businesses to monitor the status of shipments in real time, track freight costs and manage inventory levels.

Also, it enables companies to identify potential delays in the supply chain process and take proactive measures to ensure timely delivery.

Shipment tracking solutions provide businesses with full visibility into their supply chain processes, enabling them to better manage operations while improving customer satisfaction.

Real-Time Data

Real-time data helps businesses improve efficiency, reduce costs and increase customer satisfaction.

It brings solutions that enable businesses to track activities inside a warehouse in real time.

Also, it provides visibility into processes such as order fulfillment, material replenishment, and stock movements.

Having real-time data allows companies to monitor inventory levels, identify potential bottlenecks and increase the accuracy of order processing times.

These real-time solutions enable businesses to optimize the use of resources and quickly identify areas of improvement.

Real-time data solutions provide businesses with enhanced capabilities for tracking the entire supply chain process from end to end.

Also, it enables businesses to monitor shipment performance and ensure on-time delivery with precision.

Warehouse Automation

Warehouse automation is a key element of Order Fulfillment solutions.

Automation helps businesses to streamline operations, reduce costs and increase accuracy.

Warehouse automation solutions (WAS) include robotic pickers and sorting systems, automated conveyors, intelligent software, and inventory management systems.

This kind of solution enables companies to optimize their resource allocation while increasing order fulfillment accuracy.

Automation also helps businesses to reduce costs while improving Order Fulfillment speed and accuracy.

WAS enables companies to reduce manual labor costs, improve employee safety and track inventory levels in real time. It allows businesses to efficiently manage their operations while ensuring customer satisfaction.

Conclusion

Warehouse Management Systems provide a wide range of benefits for businesses to improve efficiency, reduce costs and increase customer satisfaction.

They enable companies to track activities in real-time, optimize resource allocation, and automate processes.

With the right Warehouse Management System, businesses can optimize their operations while ensuring the accuracy of Order Fulfillment.

WMS enables businesses to identify potential errors in the supply chain process, take proactive measures to reduce delays, track freight costs and monitor inventory levels.

It provides businesses with the visibility they need to optimize their processes while delivering superior customer service!