Introduction to Integrated Automation Systems (IAS)

Integrated Automation Systems (IAS) are revolutionizing how businesses operate.

By providing a comprehensive automation solution that eliminates manual labor, IAS systems help companies reduce costs, improve customer service, and increase production throughput.

Streamlining operations with IAS allows businesses to maximize profits while delivering top-notch products and services.

Interested in technologies to improve your business performance?

Here are articles on Technological Performance and Smart products!

Benefits of Integrated Automation Systems

Companies can reduce the time needed to produce products and services with an IAS. Automating the process from data collection to final product delivery ensures that all steps of operations are completed more quickly and accurately. This increased efficiency results in higher productivity levels with reduced labor costs.

Additionally, it allows businesses to provide better customer service. By automating customer service processes, companies can improve customer communication, increase response time and accuracy, and reduce the manual labor needed to manage orders.

Businesses can also optimize production throughput. Automated systems provide better control over production schedules and enable more accurate forecasting. This helps businesses maximize their profits by reducing the need for costly production delays.

Overall, automated systems provide a comprehensive solution that helps businesses reduce costs, improve customer service and increase production.

What are Examples of Automation Systems?

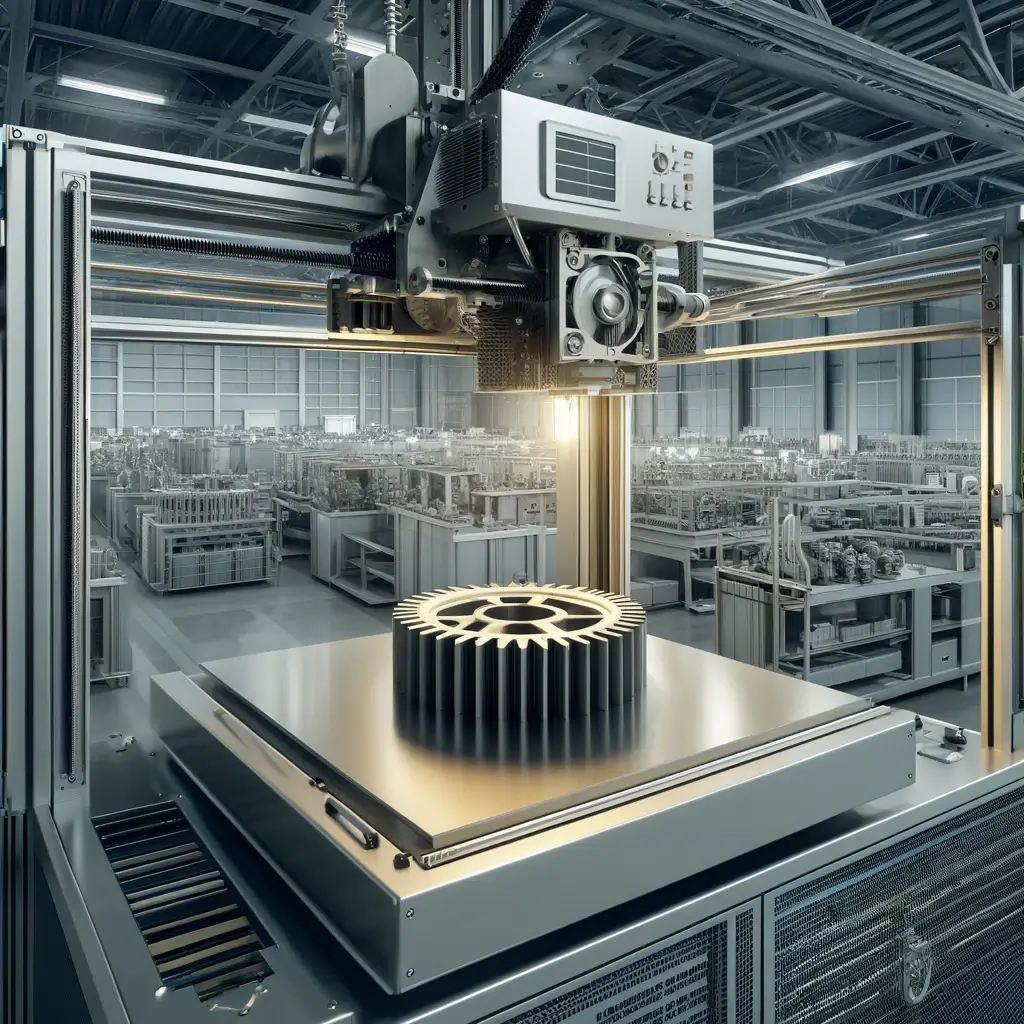

Examples of IAS include industrial robots, machine vision systems, automated data collection systems, and programmable logic controllers (PLCs).

Industrial robots streamline physical labor by autonomously executing repetitive tasks.

Machine vision systems use artificial intelligence to identify objects and help automate inspection processes.

Automated data collection systems record information more quickly and accurately than manual input.

Finally, PLCs control manufacturing processes such as sequence controls, motion control, temperature regulation, and process control.

IAS can be used in a wide variety of industries including automotive production lines, e-commerce fulfillment operations, food processing plants, and healthcare facilities.

No matter the industry or application, automation provides a comprehensive way to reduce costs while improving productivity and customer service.

Integrated Automation Systems are revolutionizing the way businesses operate and can provide a major competitive advantage in today’s economy!

Steps to Implement IAS

Here are the steps to implement successfully IAS.

1. Analyze:

Firstly, analyze the current systems and processes being used in your business to determine which areas of operations may be improved with Integrated Automation Systems.

2. Design:

Next, design a plan for implementing Integrated Automation Systems including tasks such as selecting appropriate hardware, software, and controls.

3. Implement:

Once the design phase is complete, begin to implement Integrated Automation Systems in stages until all components of operations are automated.

4. Evaluate:

After the Integrated Automation System has been implemented and operationalized, evaluate performance metrics to ensure that goals have been achieved and further improvements can be made if needed.

5. Monitor:

Lastly, monitor Integrated Automation Systems to ensure that they are functioning properly and providing the intended benefits.

The implementation of Integrated Automation Systems may seem daunting at first, but with careful planning and execution businesses can implement IAS without many problems.

Integrated Automation Systems are transforming modern businesses and can provide a major competitive advantage!

What are the major difficulties with IAS?

IAS also brings challenges. As Integrated Automation Systems become more complex, they require more expertise to operate and maintain them.

Additionally, IAS can be costly to implement, especially if the systems need to be customized or integrated with existing processes.

Furthermore, automated systems may also require specialized training for employees that are unfamiliar with the technologies used.

Lastly, Integrated Automation Systems may be vulnerable to cyber-attacks and require additional security measures to protect the data they are processing.

Despite the challenges associated with IAS, businesses can still benefit from their implementation if it is done properly and with careful consideration of potential risks. It provides a comprehensive solution that can increase productivity and reduce costs, making them an essential part of modern businesses.

By working with the right partner to implement Integrated Automation Systems, businesses will be able to get the most out of their automation investments while minimizing potential risks.

Which Business Operation Can be Automated?

Businesses have many sectors and operations and almost all of them could be automated.

For example, here are 5 operations that a business can automate :

- Accounting and financial processes

- Supply chain management

- Customer service

- Inventory management

- production

Businesses that automate their accounting and financial processes automate the process of invoicing, payments and billing.

Supply chain management is another area that IAS can improve by automating the process of ordering, shipping, and delivery.

Customer service processes can be automated to increase customer satisfaction and improve efficiency.

Automated inventory management automates the process of tracking inventory levels and reordering when necessary.

Finally, production processes can be automated in many ways, such as robotic assembly lines, automated process control, etc.

IAS offer businesses the opportunity to improve efficiency, reduce costs and gain a competitive advantage in their markets. By leveraging Integrated Automation Systems, businesses can maximize the potential of their operations while minimizing risks.

Conclusion

In conclusion, Integrated Automation Systems have the potential to revolutionize the way businesses operate, by helping them reduce costs and improve productivity.

However, IAS may require specialized training for employees and may be vulnerable to cyber-attacks, so businesses should work with a trusted partner when implementing it in order to get the most out of their automation investments. Implementing automation is an essential part of modern business success!

By following the steps outlined above, businesses can better understand IAS and its potential risks in order to ensure a successful implementation.

Automated systems can be a powerful tool for businesses, so it is important to take the time to plan and implement IAS properly!