The value chain is an essential element for all businesses. It makes it possible to identify value-added operations and competitive advantages.

On the other hand, mapping is a tool to visualize the different stages of a process, evaluate them, and draw actions from them in order to increase the efficiency of operations.

What is value?

Before continuing, it is imperative to understand the concept of value. What is value? Value is divided into three components that will be explained in the following sections.

1. Added value

The added value matches what the customer is willing to pay for his good or service. Material, labor time, etc. minimum to get what he wants.

Anything that exceeds the minimum material or labor requirements should be considered non-value added (“overquality”).

2. Essential, but non-value added

Essential, but non-value added correspond to what the customer, in an ideal world, would not want to pay, but for which he has no choice.

For example, we hire the services of a massage therapist at home. We pay $60/h for his services and $10 for transportation costs. Of course, we would like to pay only for the massage (added value). However, the professional will not teleport to our door. Travel expenses must therefore be paid (non-essential added value).

Non-value added can be reduced to improve a process, but cannot be eliminated completely. Moreover, an essential non-value added today, can become outright non-value added with technological advancements, etc.

3. Non-value added

Unlike added value, this represents anything that the customer does not want to pay and that is not essential to the manufacture or performance of a service.

For example, a banana growing company packs each fruit in a bag. The bag does nothing to help preserve the fruit or transport it, but the company raises its prices by $0.05 per banana for the cost of packaging. The consumer does not want to pay for this over-packaging, because it does not add any value to the product.

In short, the concept of value is simple, but of paramount importance. We must take the time to analyze who our customer is, what value we can bring to them and how can we reduce or eliminate the non-added value of our process.

The easiest way is to put yourself in the customer’s shoes or ask him directly what he wants in relation to our product or service.

What is the value chain?

Now that value has been defined, what do we mean by value chain?

The value chain represents a series of operations, tasks, or activities (processes) that add value to a product or service. Each step adds value to the product or service, but it reaches its full value when the chain is completed.

Indeed, few customers are willing to pay for a half-made product or a half-rendered service. Porter, the father of the concept of the value chain, explains that “the chain of activity adds more value to the products [or service] than the sum of the values of the independent activities”. (Porter, 1985)

To help understand this concept, here is a fictitious example of a value chain for a bicycle assembly company:

A: Receipt of raw materials (structure, wheel, seat, and steering wheel) / Value: $50

B : Structure Assembly / Added Value: $50

C: Assembly of wheels with the structure / Added value: $25

D: Assembly of the structure + wheel with the seat / Added value: $35

E: Assembly of the structure + wheel + seat with the steering wheel / Added value: $30

Total bike value: $250

In this example, the sum of the added values for all the independent operations is $140 (i.e. $50 + $25 + $35 + $30). The value of the finished product, the bike, once it has passed through the value chain is $250. The value of the product that has passed through each stage of the value chain is greater than the sum of the values added by each of the independent operations. When you think about it, would you be willing to pay for a bike that doesn’t have a seat? What monetary value would you give it?

Obviously, you could complete it on your own, but that would require further investment of time and money on your part. In addition, some products have no value if they are not completed at the factory because the consumer has no way to complete them by himself. For example, if it requires tools or machinery specific to the manufacturer.

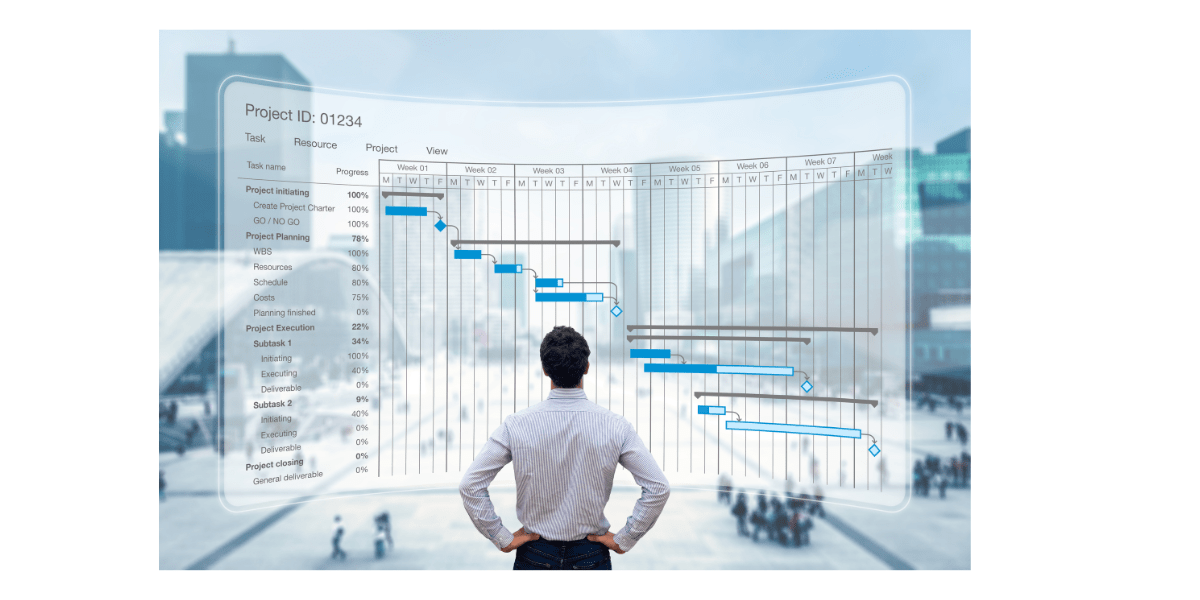

What is value stream mapping?

Value stream mapping (VSM) is a powerful tool for schematically representing the transformation process from raw material to finished product. It includes the flow of materials and information of the different stages adding value to the product or the creation of a service for which the customer is ready to pay. (Martin & Osterling, 2014)

VSM can be done for all areas of a company. Whether it is the process of sales, manufacturing, marketing, etc. The principle is to target the customer of our process and to represent it in the form of a “map” hence the term mapping. This makes it possible to clearly visualize the value operations of the company.

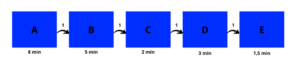

Of course, we will seek to optimize the added value and reduce or eliminate non-value added operations. In this way, we maximize the value of our product for the target customer. In addition, mapping makes it possible to target the bottlenecks of the company. That is, the process steps that directly affect the production time of a unit. Let’s take the example of our bike assembly company. Let’s consider a unit flow for this example (we produce 1 part at a time, rather than in batches of x units).

In this example, step A represents the bottleneck. Considering continuous production, we can deduce that we manufacture 1 bike every 8 minutes. Even if we improve, for example, step D of the process, and reduce the time from 3 to 1.5 minutes, we will still only do one bike every 8 minutes. When you improve the bottleneck of a company, you improve its overall productivity. This is the power of cartography. It forces us to think systematically. We think in process and system rather than in independent operation.

To better illustrate these words, imagine a waiter pouring cola. What impacts the time for which the bottle empties? This is the opening (neck) of the bottle. By enlarging the opening, the cola flows faster and the emptying time is less far. Of course, the bottleneck can move once it has been improved or from one product to another.

We can therefore prioritize the improvements that will have the greatest impact on the company. Of course, if one can easily improve the other stages than the bottleneck, it is not a bad thing to do so. This frees up resources that can perform other tasks. Especially since the labor shortage is hitting Quebec hard.

Complete Example :

For an industrial engineer like me, it is simply the best tool to analyze and optimize the value chain of a business.

If you need any assistance to realize a VSM and optimize your flow, don’t hesitate to contact us.

Référence :

https://www.larousse.fr/dictionnaires/francais/processus/64066

PORTER’S, V. C. M. (1985). “What Is Value Chain.”

Martin, K. and M. Osterling (2014). “Value stream mapping.” Estados Unidos de América: Shingo Institute