Understanding the Concept and Importance of a Continuous Inventory Control System

In today’s dynamic business environment, real-time inventory management is more critical than ever. Enter the continuous review system – a powerful tool that operates in real-time to consistently monitor inventory levels.

Imagine walking into a supermarket. Every dairy product you see on the shelves? Their stocks are managed in real time with systems like these. This technique provides instant insights for inventory managers, allowing for swift decision-making on restocking or adjusting prices.

Companies like Zara exemplify the efficacy of continuous review systems. By continuously monitoring their stock, they maintain a delicate balance, preventing both overstocking and stockouts.

Furthermore, these systems bolster product tracking to ensure accuracy and efficiency. When customers know product availability and arrival times, it fosters satisfaction and loyalty.

How Does Continuous Review System Work?

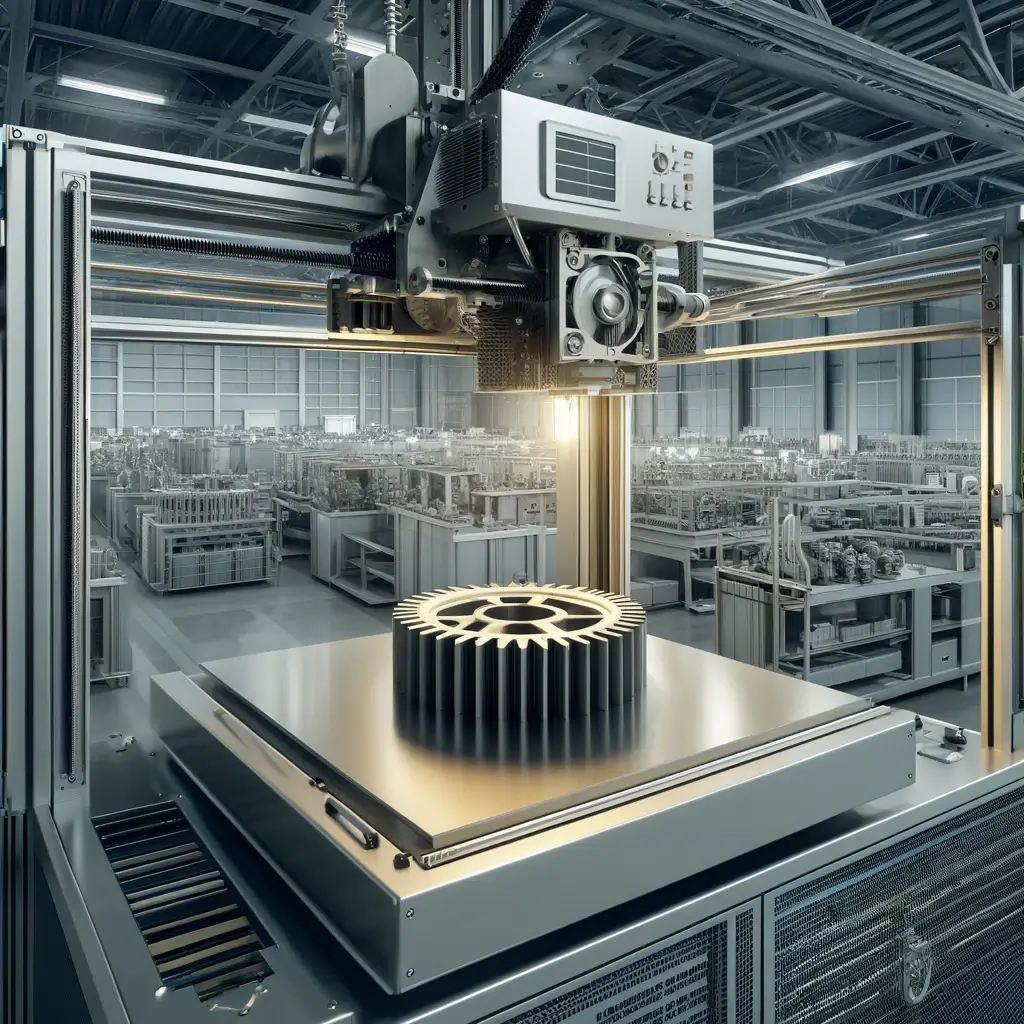

Behind the scenes of the continuous review system lies advanced technology. By harnessing tools like Radio Frequency Identification (RFID) and barcode scanners, businesses can track current stock levels, future inventory needs, and sales data seamlessly.

Included in its features, the system has an automatic reorder trigger when inventory levels dip, based on predetermined criteria. Its applicability extends across numerous sectors like retail, logistics, manufacturing, and e-commerce, among others.

Notably, continuous review systems eliminate the need for manual data entry and analysis. As technology spearheads this task, businesses have more freed-up time to address other operational areas, leading to a surge in efficiency and productivity.

Speed and accuracy are hallmarks of continuous review systems, especially when forecasting future needs. Through real-time detection of market changes and trends, this system bolsters decision-making. Think of how seasonal shifts in consumer behavior can be promptly addressed with data-backed decisions.

In short, continuous review systems offer businesses the ability to better monitor, manage, and optimize their inventory. With automated technology in place, it can save companies time and money. Since continuous review uses technologies, here is an article about performance with technology tools: Technological Performance: Road To Success!

Continuous Inventory Review Policy

In the continuous review system model, the spotlight is on three pivotal elements:

- Reorder points: This is the predetermined inventory level that signals the need for a new order. By identifying a precise reorder point, businesses can avoid the pitfalls of stockouts, ensuring that there is no disruption in sales or customer service due to the unavailability of products.

- Order quantities: This dictates the volume of products to order, based on past sales data, forecasted demand, and current stock levels. Getting the order quantity right is crucial: over-ordering can lead to increased carrying costs and potential wastage, especially for perishable goods, while under-ordering can result in missed sales opportunities.

- Lead times: This represents the duration between placing an order and its fulfillment. An accurate understanding of lead times ensures that orders are placed with enough buffer to account for any delays, making certain that products arrive just in time to replenish dwindling stock, but not so early that storage becomes a challenge.

Together, these elements serve as the foundation of the continuous review system, acting as the guiding metrics for inventory decisions. Their interplay is what ensures companies maintain optimal inventory levels, accommodating peak business times and preventing both stockouts and surplus. By meticulously calibrating these elements, businesses can significantly enhance efficiency, cut costs, and better meet customer expectations.

Unraveling Key Differences: Continuous Review vs. Periodic Review in Inventory Management

In the realm of inventory management, businesses are often faced with a strategic decision between the Continuous Review and Periodic Review systems. Both systems have their respective merits and potential drawbacks.

For decision-makers, understanding the nuances of each system is paramount to optimize inventory processes and achieve desired business outcomes.

Below is a comparative analysis of the two systems, breaking down their core functionalities and distinguishing features:

|

Aspect/Feature |

🔄Continuous Review System | 📆 Periodic Review System |

| Automation Level | 🔵Fully Automated | 🔴Manual (with some automated components possible) |

| Monitoring Frequency | 🔵Real-time, continuous | 🔴At set intervals |

| Adjustment Speed | 🔵Almost instantaneous | 🔴Only after periodic reviews |

| Need for Manual Review | 🔵Minimal, as technology largely oversees operations | 🔴Regularly required |

| Cost Efficiency | 🔵Generally more cost-efficient due to reduced manual errors | 🔴Can be more costly if not managed efficiently |

| Response to Demand Shift | 🔵Rapid & accurate | 🔴Slower, potentially missing sudden changes |

| Best Suited For | 🔵Businesses requiring continuous analysis | 🔴Organizations with periodic or changing needs |

| Overall Responsiveness | 🔵High, due to real-time monitoring | 🔴Moderate, given its interval-based nature |

Unveiling Financial Implications: The Price Companies Pay for Subpar Inventory Management

Mistakes in inventory management are expensive. Picture this: worldwide, retailers are losing a staggering $1.75 Trillion annually due to poor inventory practices.

Having excessive inventory results in elevated carrying costs, potential devaluation, and missed opportunities. Conversely, too little stock can cause shortages, lost sales, and customer dissatisfaction.

Additionally, bad inventory management can lead to incorrect pricing or inventory count inaccuracies, which can result in issues with inventory audits and inventory taxes. The cost of inventory management mistakes can be significant, resulting in lost profits, customer dissatisfaction, and a damaged reputation.

It is essential for businesses to have an inventory management strategy in place to ensure inventory accuracy and availability, as well as minimize inventory costs.

Conclusion

In the ever-evolving world of business, the continuous review system emerges as a frontrunner. Its strengths in forecasting, accounting, and rapid responsiveness to market changes are unmatched.

For businesses seeking continuous analysis and prompt reactions, it is a formidable tool, overshadowing periodic review systems in efficiency.

Source :

7 Indicators You’re Managing Bad Inventory (and How to Fix It), retalon.com, https://retalon.com/blog/bad-inventory#:~:text=Worldwide%2C%20retailers%20are%20losing%20%241.75,accepted%20as%20the%20status%20quo.