Welcome to the evolving world of automation where collaborative robots, or ‘cobots’, are revolutionizing the way small and medium-sized enterprises (SMEs) operate in Industry 4.0. With a projected market value of over 1 billion dollars by 2025, cobots are not just a fleeting trend but a cornerstone in the future of manufacturing and production. (Statista, 2023)

Unlike traditional industrial robots, cobots are designed to work alongside humans, offering flexibility, efficiency, and a safer working environment. This surge in cobot adoption is particularly notable in SMEs, where their versatile applications range from assembly and packaging to quality control and beyond.

In this article, we delve into the world of cobots and their transformative role in SMEs, unlocking potential and driving innovation in an era that demands adaptability and efficiency.

What is a Cobot?

Cobots, or collaborative robots, are designed to work alongside humans in a shared workspace, enhancing efficiency and safety. Their versatility makes them a valuable asset across various industries. Let’s explore some key applications:

- Manufacturing: In the automotive industry, cobots are used for tasks like assembling parts, machine tending, and quality inspections. Their precision and consistency ensure high-quality production with reduced errors. In SMEs, cobots can be used to perform welding, bending, and other intricate manufacturing processes. These tasks often require high levels of accuracy and repeatability, which cobots can achieve more efficiently than manual labor.

- Healthcare: In the medical field, cobots assist in laboratory research, handling delicate tasks like sample preparation and analysis. They also play a role in patient rehabilitation, aiding in physical therapy exercises with precise, gentle movements.

- Retail and Logistics: Cobots streamline processes in warehouses and distribution centers. They are involved in picking and packing orders, handling inventory, and even assisting in restocking shelves in retail environments.

- Food and Beverage Industry: Cobots are revolutionizing food production by performing tasks like packaging, sorting, and even delicate operations like cake decoration, ensuring hygiene and efficiency.

- Agriculture: In agriculture, cobots aid in processes like planting, harvesting, and sorting. They help in handling delicate produce and performing repetitive tasks, increasing productivity and reducing labor costs.

- Education and Research: In academic settings, cobots serve as educational tools, helping students and researchers in experiments and prototype development, offering hands-on experience in robotics and automation.

Each of these applications demonstrates the adaptability of cobots in various sectors. Their ability to learn and perform tasks with precision and safety makes them an indispensable tool in the modern industrial landscape, opening new horizons for innovation and productivity.

Cobots or Robots? Understanding the Difference

While both cobots (collaborative robots) and traditional robots are integral to the automation landscape, they serve distinct roles and have different capabilities.

Understanding the differences between collaborative robots (cobots) and traditional industrial robots is crucial in choosing the right technology for your specific needs. Each has its own set of strengths and applications, making them suitable for different environments and tasks.

To provide a clearer perspective and assist you in making an informed decision, here is a table comparing key aspects of cobots and traditional robots:

| Aspect | Cobots | Traditional Robots |

|---|---|---|

| Agility vs. Speed | Designed for agility and flexibility, adaptable to various tasks and environments. | Excel in speed, ideal for high-volume, repetitive tasks in large-scale production. |

| Safety | Can safely work alongside humans without extensive barriers due to advanced sensors and safety features. | Often require separate workspaces and safety barriers due to their speed and force. |

| Programming | User-friendly; can be easily programmed by employees without specialized training. | Require complex programming and setup, typically needing specialized personnel. |

| Scalability | Highly scalable and flexible; easily moved and reconfigured for different tasks, making them cost-effective for variable production needs. | Fixed in place and specialized for specific tasks, less flexible but highly efficient for those operations. |

| Cost | Lower initial investment and minimal installation costs, making them accessible for SMEs. | Higher initial cost but can offer higher throughput, representing a valuable long-term investment for larger firms. |

What is Manufacturing Agility?

The concept of manufacturing agility refers to the ability of a production process to rapidly adapt to changes and variations, be it in product design, quantity, or manufacturing process.

Cobots play a pivotal role in enhancing this agility, particularly in SMEs. Here are some real-world examples illustrating this impact:

- Customized Product Manufacturing: In the bespoke manufacturing sector, an SME specializing in custom furniture uses cobots to quickly switch between different product designs. The cobots are programmed to handle various tasks like cutting, drilling, and assembly for different furniture designs, drastically reducing the changeover time between batches.

- Automotive Component Assembly: A small automotive parts manufacturer employs cobots to adapt to fluctuating demand. With cobots, they can rapidly scale production up or down, accommodating short runs of specialized parts without the need for extensive retooling or downtime.

- Electronics Sector: In electronics assembly, an SME utilizes cobots for tasks like circuit board assembly and testing. The cobots’ precision and ease of reprogramming allow the company to swiftly adapt to new product designs or updates, ensuring they stay ahead in a rapidly evolving market.

- Food and Beverage Industry: A craft brewery has integrated cobots into its bottling and packaging process. The cobots are adaptable to different bottle sizes and labeling requirements, allowing the brewery to offer a wider range of products without compromising efficiency.

- Pharmaceuticals: In a small pharmaceutical company, cobots handle delicate tasks such as pill sorting and packaging. Their ability to quickly switch between different drug types and packaging formats enhances the company’s ability to respond to market changes and regulatory requirements.

These examples demonstrate how cobots contribute significantly to manufacturing agility in SMEs across various industries.

By enabling rapid adaptation and customization, cobots help these businesses stay competitive and responsive to customer needs in a dynamic market environment.

Cobots: Pioneers of Agile Manufacturing in SMEs

Collaborative robots, or cobots, are revolutionizing agility in small and medium-sized enterprises (SMEs). They offer a range of advantages that are particularly beneficial in the fast-paced world of manufacturing.

| Advantage | Details and Impact on SMEs |

|---|---|

| Versatility and Flexibility | Cobots can be quickly reconfigured for various tasks, allowing SMEs to adapt rapidly to changing market demands or customer preferences. This versatility makes production lines more dynamic and responsive. |

| Speedy Installation | Cobots are designed for easy and fast installation. This reduces downtime and accelerates the implementation of new production processes, enabling SMEs to swiftly respond to market shifts. |

| Ease of Use and Training | The intuitive programming of cobots makes them easy to use, enabling quick employee training. This reduces the dependency on specialized labor and allows for a more adaptable workforce. |

| Enhanced Productivity | By combining flexibility, quick installation, and user-friendliness, cobots significantly boost SMEs’ productivity and competitiveness in the market, particularly in rapidly changing environments. |

In summary, cobots are not just an automation solution; they are a strategic asset for SMEs aiming to enhance their agility and responsiveness in an ever-evolving marketplace. Their role in modern manufacturing is pivotal in empowering SMEs to achieve greater efficiency and competitiveness.

Enhancing SME Operations: The Multifaceted Benefits of Cobots

Small and Medium-sized Enterprises (SMEs) stand to gain significantly from the adoption of collaborative robots, commonly known as cobots. These advanced tools are not just about automation; they are about enhancing human potential in the workplace.

Let’s delve into the multifaceted benefits that cobots offer to SMEs:

- Boosted Productivity: One of the most immediate impacts of cobot integration is a notable surge in productivity. Cobots excel at taking over repetitive or physically demanding tasks, which liberates human employees to focus on more complex, creative activities that require human intelligence and finesse. This not only optimizes the workflow but also addresses labor shortages effectively, enabling a considerable uptick in overall output.

- Enhanced Workplace Safety: Safety is paramount in any industry, and cobots contribute significantly in this arena. By undertaking hazardous tasks themselves, cobots minimize human exposure to risky environments. This aspect is especially vital for SMEs, where extensive safety training and procedures might be financially burdensome. The integration of cobots can lead to a safer workplace, reducing the likelihood of accidents and injuries.

- Increased Operational Agility: In today’s fast-paced market, agility is key. Cobots are renowned for their versatility and ease of reconfiguration. This allows SMEs to quickly adapt to new tasks or changing production demands, giving them a competitive edge in a market that values flexibility and rapid response to consumer needs.

- Revitalizing Employee Roles: Far from rendering human roles obsolete, cobots can actually make certain tasks more engaging for employees. By automating mundane aspects of a job, employees are freed to focus on more rewarding and intellectually stimulating tasks. This shift can lead to improved job satisfaction and higher retention rates. For instance, in the food and beverage industry, cobots assist with repetitive tasks like packing and labeling, thus allowing employees to engage in more creative or customer-focused roles.

- Competitive Advantage in the Market: The integration of cobots goes beyond internal benefits; it also positions SMEs more competitively in the marketplace. With increased efficiency, safety, and agility, SMEs can offer higher-quality products and services, respond more swiftly to market changes, and maintain a more satisfied and motivated workforce.

To conclude this section, the strategic adoption of cobots is a game-changer for SMEs, bringing about advancements in productivity, safety, agility, and employee engagement. This technological leap not only enhances current operations but also paves the way for future growth and competitiveness in a dynamic market.

Navigating Challenges with Effective Solutions in Cobot Integration

While cobots offer numerous benefits, their integration also presents certain challenges. Here, we explore these challenges with concrete solutions to ensure successful implementation in SMEs:

- High Initial Investment

- Solution: Opt for cobot leasing programs or consider government grants and subsidies available for small businesses adopting new technologies. Additionally, focus on long-term ROI rather than upfront costs, as cobots significantly reduce long-term operating expenses.

- Employee Resistance to Change

- Solution: Conduct training sessions to educate employees on the benefits and safe operation of cobots. Encourage a culture of innovation where employee input is valued in integrating new technologies. Highlight how cobots will enhance their work, not replace it.

- Integration with Existing Systems

- Solution: Work with cobot suppliers who offer customized integration services. Conduct a thorough analysis of current processes to identify the best points of cobot integration. Utilize cobots with advanced AI capabilities that can adapt to existing setups.

- Keeping Up with Rapid Technological Advances

- Solution: Partner with technology providers for regular updates and maintenance. Attend industry workshops and seminars to stay informed. Consider scalable cobot models that can be upgraded as technology advances.

- Ensuring Safety in Collaborative Environments

- Solution: Implement cobots with advanced safety features like collision detection and responsive stop mechanisms. Regularly review and update safety protocols. Conduct risk assessments to customize safety measures around cobot operations.

Addressing these challenges with targeted solutions will more effectively leverage the potential of cobots. This will also ensure smoother integration and maximized benefits from these advanced technological tools!

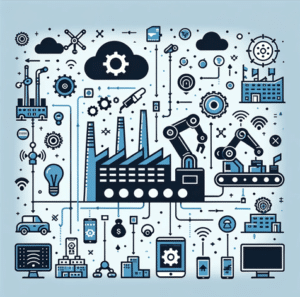

Cobots: Catalysts of Industry 4.0 and the Future of Intelligent Manufacturing

Cobots are integral to Industry 4.0, the latest industrial revolution focused on creating intelligent, interconnected factories. In these smart manufacturing environments, cobots collaborate and communicate with other machines, enhancing efficiency and productivity through shared data and insights.

As Industry 4.0 continues to evolve, the adoption of cobots is becoming increasingly crucial. They represent a significant leap toward more automated, flexible, and efficient manufacturing processes.

As more businesses integrate cobots, we are witnessing the gradual shaping of the fourth industrial revolution. Cobots are not just a part of this industrial transformation; they are at its forefront, heralding a new era of advanced, intelligent manufacturing.

Industry 4.0: Tools and Principles

The fourth industrial revolution is composed of 12 principles of design and 13 tools. The table below presents each of them. As you can see, Cobots are parts of the 4.0 tools. (Ghobakhloo, 2018)

Principles of Design

|

Principles of design |

Description |

| Smart Factories | Smart factories are designed to be more flexible, efficient, and responsive to changes in the market.

They use advanced technology to manage the entire production process from start to finish. This includes everything from design and planning to raw materials, manufacturing, and delivery. |

| Smart Products | Smart products, or connected products, are objects connected to the internet with the aim of sharing information about themselves, their environment, or its user.

It has three main components: the physical, “intelligent” and connectivity components. |

| Virtualization | Virtualization is the creation of a virtual (rather than actual) version of something, such as an operating system, a server, a storage device, or network resources. |

| Horizontal Integration | Horizontal Integration is the process of a company expanding its product line or services to include products or services that are at the same level of development as its current products and services.

It can also refer to the process of a company acquiring another company that is at the same stage of development, in order to expand its market share or product line. Translated from (Quebec’s office of the French language, 1996) |

| Vertical Integration | Vertical Integration is the process in which multiple steps in the production of a good or service are controlled by a single company or organization.*

This can be done either by consolidating different stages of production under one roof or by owning the company that provides the input needed for the next stage in production.* |

| Service Orientation | Service Orientation is a design approach that focuses on creating services that can be reused in different contexts and across different platforms.

It is an important concept in the world of software development, and it is becoming increasingly relevant in other industries as well. |

| Internet of Service (IoS) | Internet of Service (IoS) is the fourth industrial revolution that enables machines to communicate with each other to share data and information.

Cobots are an important part of IoS, as they are connected and can communicate with each other to help increase productivity, safety, agility, and competitiveness in the marketplace. |

| Real-Time Capability | Real-Time Capability is the ability to process and respond to data and information in real-time.

This is an important part of IoS as it allows machines to communicate with each other quickly and efficiently. Also, it enables businesses to react to any change in their systems as soon as something happens (or even before something (bad) happens!) |

| Decentralization | “Industry 4.0 supports decentralization, which enables different systems inside a smart factory to make decisions in a way autonomous and this, without deviating from the ultimate goal of the company” (Gilchrist, 2016) |

| Interoperability | “Interoperability refers to the ability of all components [of a process] to connect, communicate and operate together via the Internet of Things.”

This is an important principle of Industry 4.0 because processes no longer do anything but follow “a predetermined recipe or method.” (Gilchrist, 2016) |

| Modularity | Modularity or modular design consists of designing a standard platform per product family on which modules (or options) are added to customize and enhance the product.* |

| Social Responsability | In his article, Ghobakhloo (2018) talks about corporate social responsibility, because Industry 4.0 is very much about setting up new technologies and this creates fear among employees.*

Indeed, many believe that the arrival of technologies will “eliminate” jobs because machines will replace day laborers.* However, as Ghobakhloo (2018) explains, technologies are more likely to create new jobs than to eliminate them.* According to the author, companies undertaking a digital shift (4.0) must instead prepare to train their staff because industry 4.0 requires a little labor more specialized.* It is therefore unskilled labor that will be most affected by |

*Parts of the table’s text belong to the Master’s dissertation of the author. Therefore, it is our “intellectual property” and some of the text is directly translated from it. (Abdulnour, 2021)

Tools of Industry 4.0

| Tools |

Description |

| Internet of Things (IoT) | “Set of objects connected to the Internet capable of communicating with humans, but also with each other, thanks to electronic identification systems, to collect, transmit and process data with or without human intervention.” (Translated from Quebec’s office of the French language, 2015) |

| Cyberphysical system (CPS) | Cyber-physical systems are systems “integrating electronics and software, sensors and actuators and equipped with communication capability”.*

They enable the collection of real-time data on a product, a process, and its environment.* Using their communication skills, CPSs can “act in |

| Big Data | “Big data refers to data sets that are too large or complex to be dealt with by traditional data-processing application software.

Data with many fields (rows) offer greater statistical power, while data with higher complexity (more attributes or columns) may lead to a higher false discovery rate.” (Wikipedia, 2022) |

| Cloud Computing | “Cloud computing is the delivery of computing services—including servers, storage, databases, networking, software, analytics, and intelligence—over the Internet (“the cloud”) to offer faster innovation, flexible resources, and economies of scale.” (Azure Microsoft, 2022) |

| Automation and Robotization (Cobots) | Automation, robotization, and the use of cobots allow companies to increase their productivity, quality, etc.

It also helps businesses to continue growing in the context of a labor shortage! |

| Cyber Security | Connectivity, automation, etc. brings new challenges in terms of security. To protect data and all of their systems, businesses need to focus on cybersecurity to keep hackers away!

Simply put, cybersecurity is the practice of protecting an organization from digital attacks. No matter how (processes, technologies, technicians, etc.). |

| Additive Manufacturing | Additive manufacturing is another way of saying 3D printing. It consists of using a computer to model a part and then using a 3D printer to manufacture it.

3D printers are fed by a plastic reel that goes through a heated nozzle to melt it. Then it adds layers by layer to fabricate the desired part. |

| Simulation | Simulation (of industrial systems) refers to the “ability to simulate the entire production floor operations. These simulations are the virtual mirror of the world physics, i.e. machines, products, and humans” (Beaudoin, et al., 2016).*

To do this, the desired system must be modeled using computer tools or a “frame 21 digital”. This then allows different scenarios to be tested on the system and “to obtain numerical values” concerning, for example, the rate of use of resources, “the rate of use of work cells and the bottleneck”, etc. (Caggiano, |

| Augmented Reality | Tzimas, Vosniakos, & Matsas (2019) describe augmented reality (AR) as a representation of the real world, in real-time, augmented by representations created by computers.*

This allows the operator to instantly receive information extra to do their job. Finally, unlike virtual reality (VR), AR adds elements to the real environment.* VR, on the other hand, replaces entirely the real environment with a virtual environment.* |

| Semantic Technology | In the Larousse dictionary, semantics is defined as the “study of the meaning of linguistic units and their combinations.” (Larousse, 2022)

As far as semantic technologies are concerned, the Expert System company provides the following definition: “Semantic technology, in its simplest definition, refers to software capable of analyzing texts and associating a meaning with each word”. To do this, the software uses “machine learning”, as well as “algorithms of artificial intelligence” (Expert. ai, 2019). |

| Internet of Data | The internet of data is the internet that is concerned “with the means of efficient transfer, storage, management and processing of data” in an environment where a large amount of data is produced by a large number of devices, machines, etc.*

Some authors even go so far as to say that the Internet of data is “the extension of the Internet of Things into the digital world”.* (Ghobakhloo, 2018). |

*Parts of the table’s text belong to the Master’s dissertation of the author. Therefore, it is our “intellectual property” and some of the text is directly translated from it. (Abdulnour, 2021)

Conclusion

Cobots are an important part of Industry 4.0, the fourth industrial revolution. They are based on the idea of the intelligent factory, where collaborative robots and other machines are connected and can communicate with each other to share data and information.

The adoption of cobots offers a number of advantages for SMEs. Cobots can help increase productivity, safety, agility, and competitiveness in the marketplace. Despite the many advantages of cobots, there are also some challenges that SMEs face when implementing them.

One of the biggest challenges is the high cost of cobots. Cobots are still a relatively new technology and they can be expensive to purchase and maintain. This can be a barrier for SMEs who may not have the capital to invest in cobots. However, some investment incentive programs could help with this issue!

Another challenge for SMEs is the lack of cobot expertise. As cobots become more popular, there is a growing demand for cobot experts who can help with installation, programming, and maintenance. This can be difficult for SMEs to find since there are currently few cobot experts available.

SMEs may also need to make changes to their workplace in order to accommodate cobots. For example, changes may need to be made to workstations, employee training, and safety procedures.

Industry 4.0 is composed of 12 principles of design and 13 tools that are described in some tables in the text. Cobots are parts of the fourth industrial revolution tools (automation and robotization).

To conclude, the benefits of cobots can easily outweigh the challenges of implementation for SMEs. As cobots become more popular, we will see their true impacts on the business world!

Reference

Azure Microsoft, 2022. What is Cloud Computing? Taken from: https://azure.microsoft.com/en-us/resources/cloud-computing-dictionary/what-is-cloud computing/#:~:text=Simply%20put%2C%20cloud%20computing%20is,resources%2C%20and%20economies%20of%20scale.

Expert. ai., 2022. La technologie sémantique pour le Big Data : analyse, défense, sécurité et renseignement. Translated from: https://www.expert.ai/fr/technologie-semantique/ Consulted on November 17, 2022.

Gilchrist, A. (2016). Industry 4.0. The industrial Internet of Things. Apress.

Hohmann, C. (2017, octobre 29). Qu’est-ce qu’un système cyber-physique. Translated from: http://christian.hohmann.free.fr/index.php/usine-du-futurI744-quest-ce-quun-systeme-cyber-physique.

Larousse. (2022). Sémantique. Translated from: https://www.larousse.fr/dictionnaires/francais/s%C3%A9mantique/71932#:~:text=%EE%A0%AC%20s%C3%A9mantique&text=1.,v%C3%A9rit%C3%A9%20ou%20de%20leur%20fausset%C3%A9. Consulted on November 17, 2022.

Quebec’s office of the French language. (2015). Internet des Objets. Translated from: http://gdt.oqlf.gouv.qc.ca/ficheOqlf.aspx?Id_Fiche=26529845. on November 16, 2022.

Quebec’s office of the French language. (1996). Intégration Horizontale. Translated from: https://gdt.oqlf.gouv.qc.ca/ficheOqlf.aspx?Id_Fiche=8394990

Wikipedia contributors. (2022, November 9). Big data. In Wikipedia, The Free Encyclopedia. Retrieved 20:29, November 16, 2022, from https://en.wikipedia.org/w/index.php?title=Big_data&oldid=1120846918